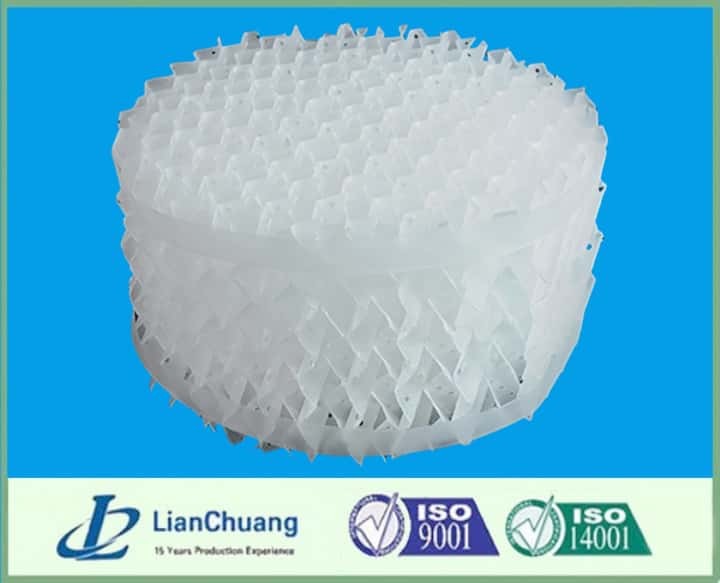

Product Description

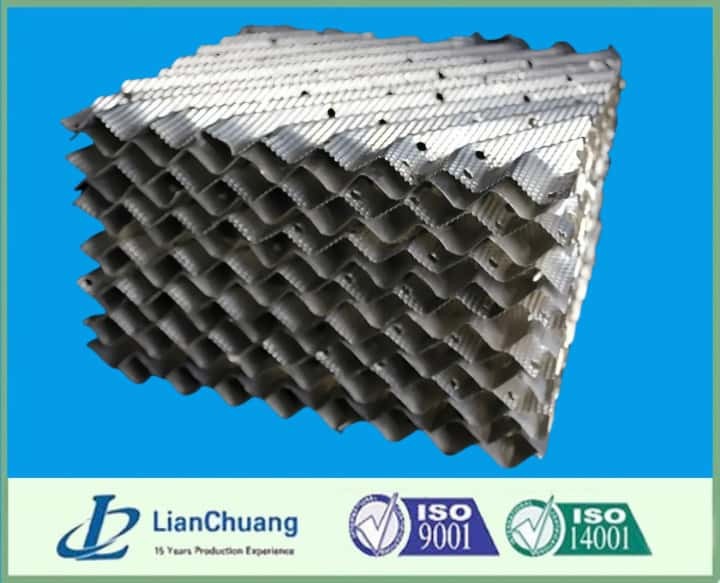

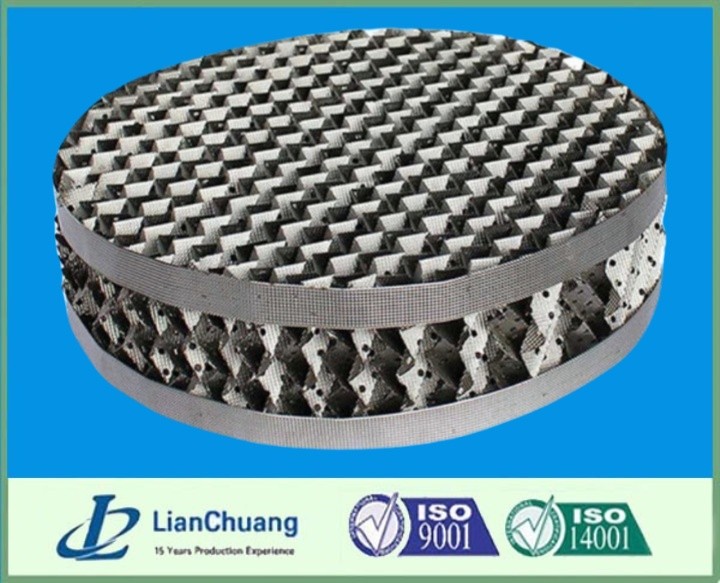

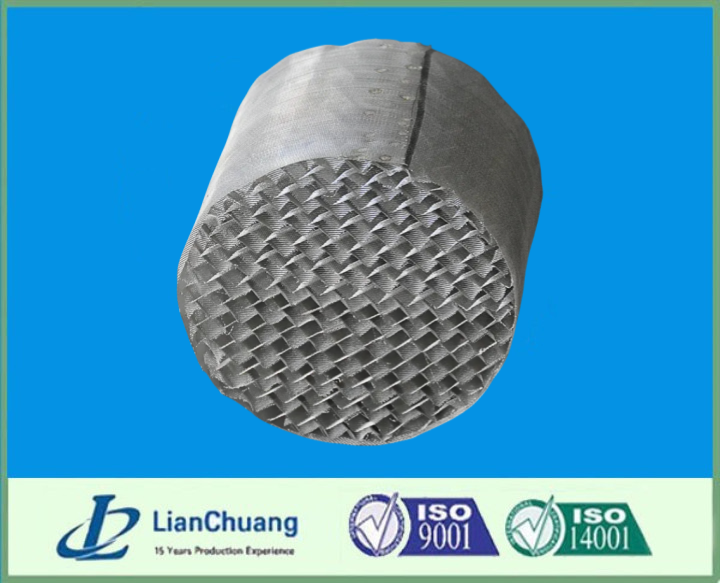

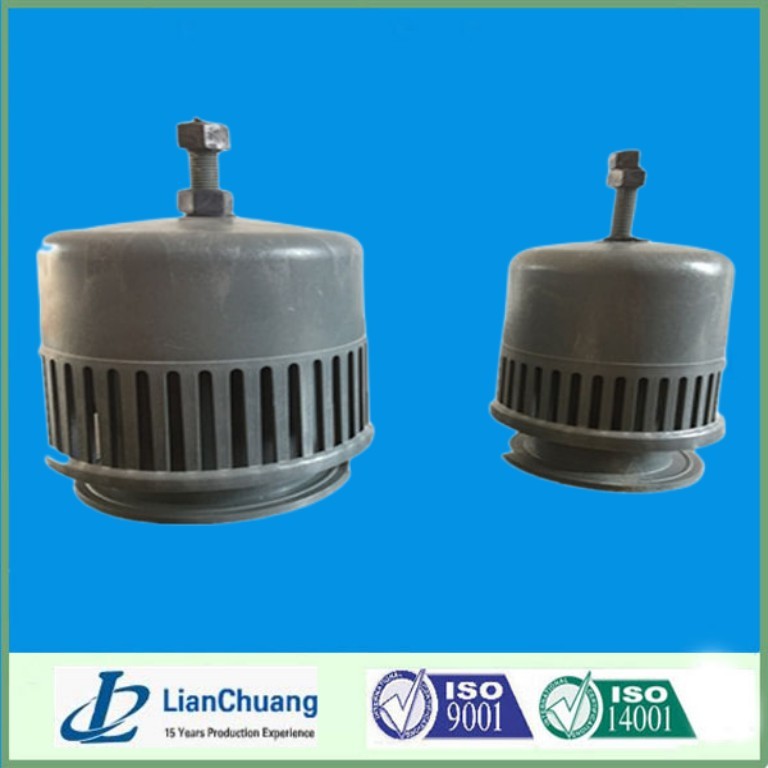

plastic wire mesh demister is used for wire mesh demister, oil-gasseparator, dust remover,dedusting apparatus, environmental protection device, various separating and filtering devices, filtering eliminate for auto and tractor, sealing, shock absorption, muffling and purifying components for auto, as wellas used for electromagnetic interference and shielding devices for electric apparatus.With the aid of latte technology, we manufacture precision designed PP Wire Mesh Demister or pp demister pad that are metal & PP wire knitted pads with maximum opening and contact surface. Available in various aperture sizes and dimensions, it's useful to trap liquid droplets escaping along with vapor that prevents high boiler products droplets carry-over into low boiler top condenser.

Features of Wire Mesh Demister:

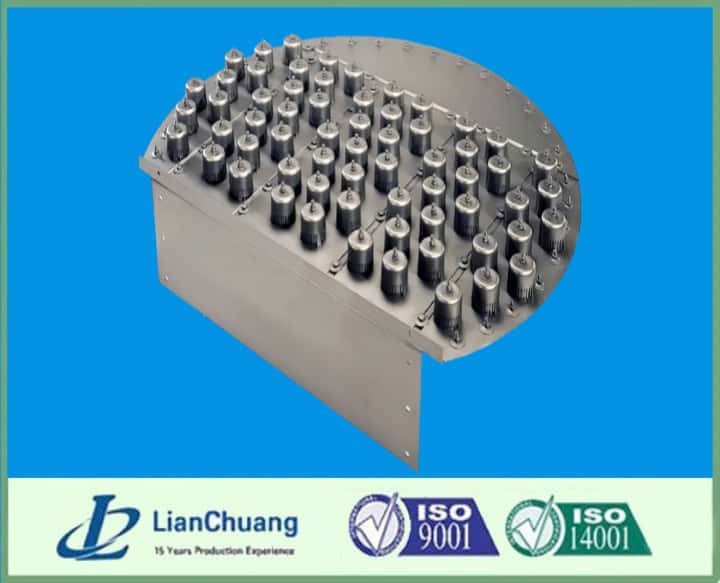

1. Easy to install in all process equipment

2. Most cost-effective solution when equipment sizes are set by other requirements

3. High efficiency with low pressure drop

4. Emergency delivery available

Application:

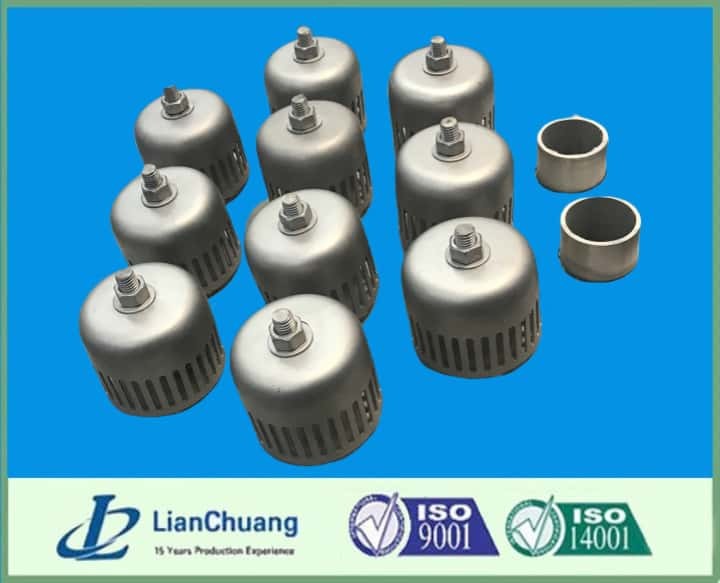

1.Vacuum Tower - The treatment quantity by the demister goes up by 35%.The quality of oil gas is improved.

2.Absorber - Some gasoline plants use a glycol absorber (Demister mounted) so the installation cost is being repaid within a month.

3.Knockout Drums and Separators- If Demister is used,1/3 inch drum is sufficient.

4.Gas Separator Vessels - Hydrocarbon in gases is collected so gas of 1/0.1 billion purity is produced out .

5.Evaporator - Product loss goes down and purity is remarkably improved.

6.Scrubber - In the field of caustic soda ,the demister is used to privent air pollution.

7.Distillation Column - If Demister is used ,the cost for distillation goes up ,the quantity of treatment incrases by 20%,and purity is remarkably improved.

8.Dust collectors - The dust collector of a wet type has excellent collection capacity.

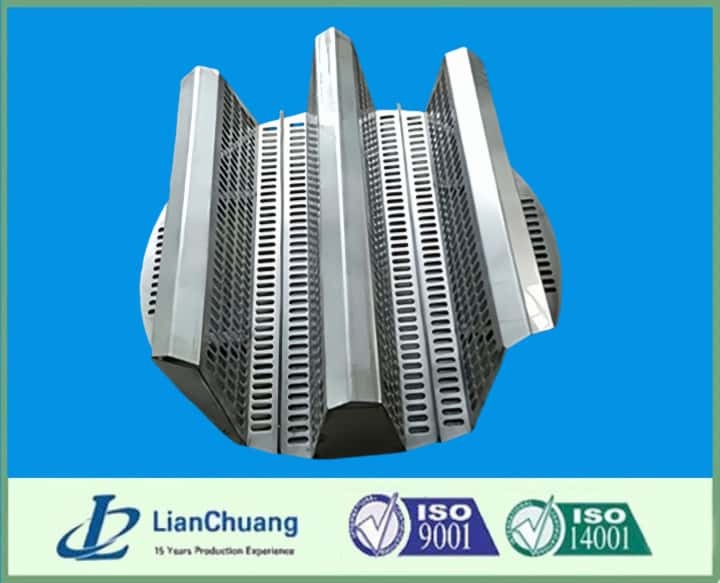

Type | Specification |

Standard type | 40-100 60-150 105-300 140-400 160-400 200-570 |

High-efficiency type | 60-100 80-100 80-150 90-150 150-300 200-400 300-600 |

High-penetration type | 20-100 30-150 70-400 100-600 170-560 |

Damping type | 33-30 38-40 20-40 26-40 30-40 30-50 48-50 30-60 30-80 50-120 |