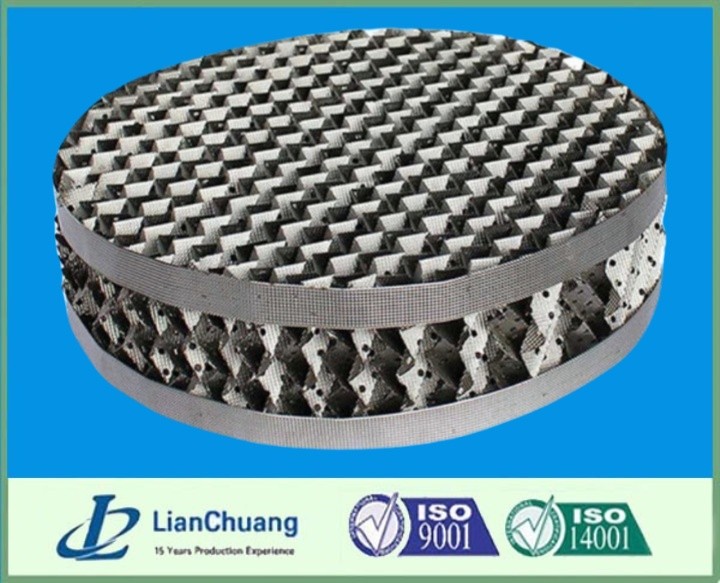

Product Description

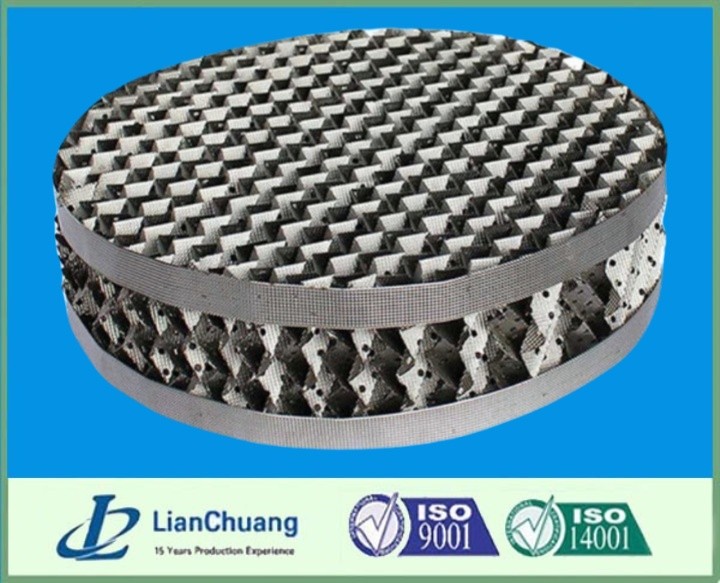

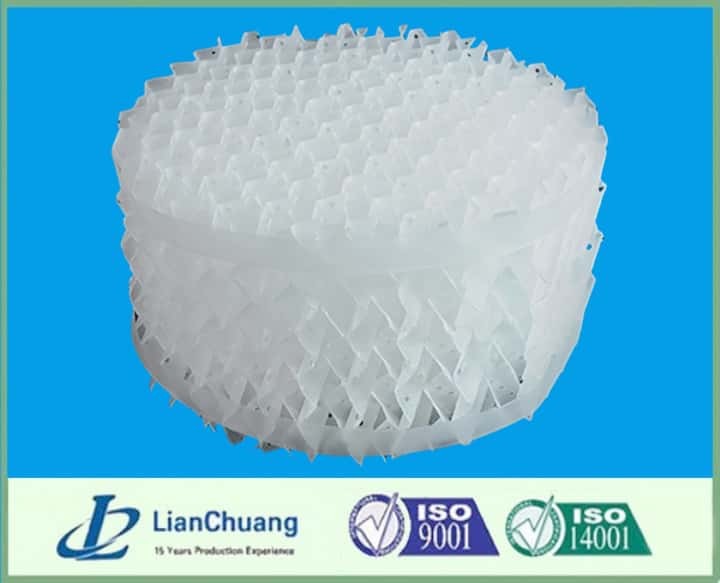

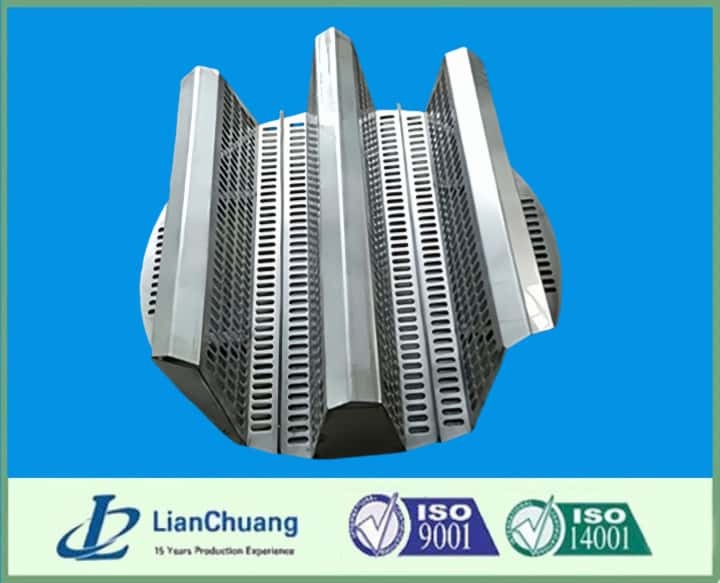

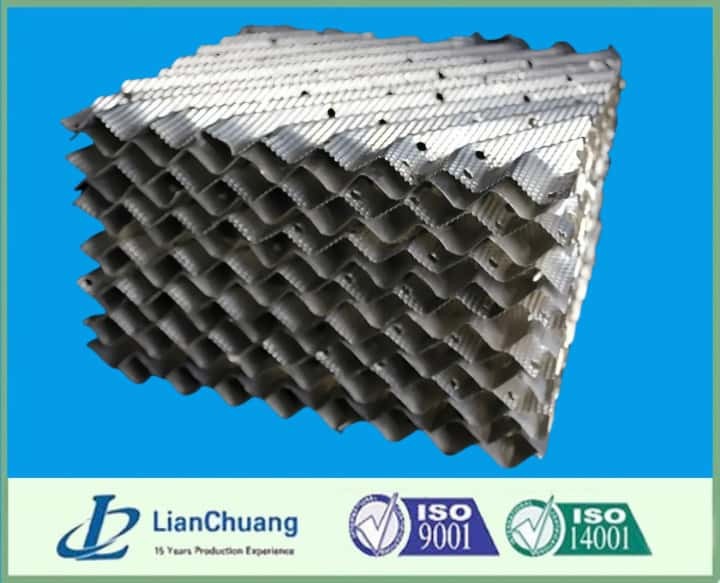

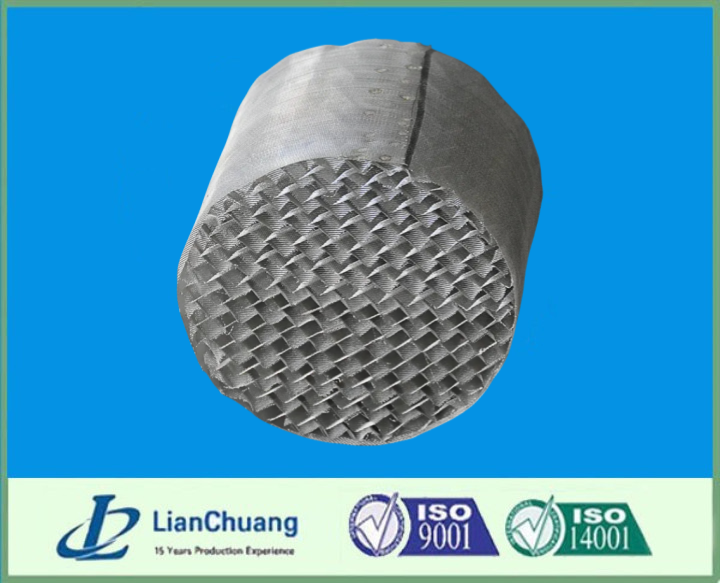

mellapak packing is one kind of metal structured packing, it is made of perforated plate with channel corrugation on surface, and remains structured feature of metal wire gauze packing. It strengthens uniform liquid distribution and surface wetting ability, which increase mass transfer efficiency. It is a structured packing,whicn uniform geometry distribute in tower.This packing limits gas-liquid flow,improve channel flow and wall flow phenomenon,lower pressure drop. Meanwhile,it also provide more bigger surface area and achieve better mass transfer,heat transfer perfromance.The ealiest Metal structured packing was invented by Swiss Sulzer,called Mellapak packing.After then,the structured packing was widely promoted by many companies. such as Swiss Kuhni's Rombopak,Germany Monlz's Montz-pak,American Norton's Intalox Structured packing, Jaeger's Mix-pak, Raschig Ring's Ralu-pac and so on.Metal structured packing is available in a wide range of materials; include stainless steels, 304, 316, 316L, Carbonsteels. Aluminium, copper bronze etc. Further materials available on request.

Main Benefits:

1.Mellapak and MellapakPlus offer significantly lower pressure drops compared to conventional structured packings.

2.For new columns, MellapakPlus allows for a smaller column diameter.

3.In existing columns, MellapakPlus increases capacity while maintaining the same efficiency.

4.MellapakPlus provides up to 50% higher capacity at the same number of theoretical stages per meter compared to conventional Mellapak.

Key Characteristics:

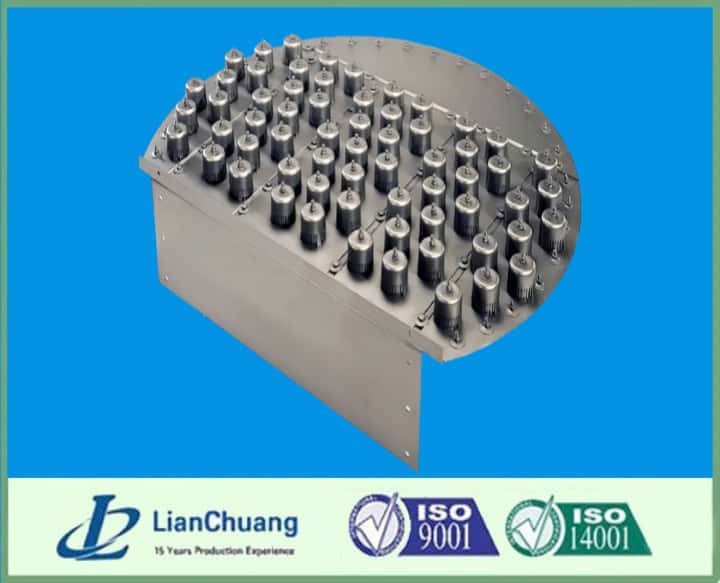

1.Pressure drop per theoretical stage: 0.3 - 1.0 mbar.

2.Pressure drop at 70-80% flooding: approximately 2 mbar/m.

3.Minimum liquid load: around 0.2 m³/m²h.

4.Maximum liquid load: more than 200 m³/m²h, typically in desorption columns.

Main Applications:

1.Chemical industry: used in processes like ethyl benzene/styrene, tall oil, cyclohexanone/cyclohexanol, and air separation.

2.Petrochemical industry: applied in quench columns, C3- and C4- splitters, and xylene splitters.

3.Refineries: employed in vacuum and atmospheric distillation columns.

4.Absorption: used in natural gas drying, CO2 and H2S absorbers and strippers, ethylene oxide absorbers and strippers, and acrylonitrile absorbers.

5.Mellapak structured packing is suitable for a wide range of applications, from low vacuum (1 mbar) to high-pressure operations.

Material:

1.Stainless steels such as 304, 316L, 316Ti, 321

2.Carbon steel, aluminum, copper, titanium, Monel and other corrosion resistant alloy

3.Other materials are available on request