Product Description

Mutag BioChip™ 30 is a cutting-edge biofilter media designed for use in Moving Bed Biofilm Reactor (MBBR) systems, specifically engineered to optimize the biological treatment of wastewater. Developed by leveraging over 20 years of experience in MBBR technology, the Mutag BioChip™ has become the heart of modern fluidized bed processes, delivering unparalleled performance in nitrification, denitrification, and biochemical treatment processes.

Key Features of mutag bio chip

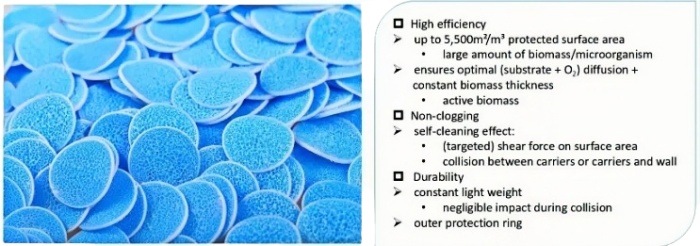

Extensive Active Surface Area

The Mutag BioChip™ provides an impressive active surface area of over 5,500 square meters per cubic meter. This large surface area ensures the attachment and growth of a high concentration of microorganisms, which are crucial for the efficient breakdown of organic pollutants and the removal of nitrogen compounds, such as ammonium, from wastewater.

Advanced Biofilm Protection

The biochip's innovative design includes a protected active surface, which houses the fixed microorganisms responsible for various biochemical water treatment processes. This protection allows for stable and reliable operation, even in conditions with high pollutant loads.

Durability and Efficiency

The Mutag BioChip™ is constructed from high-quality, virgin PE material, ensuring long-term durability and resistance to wear and abrasion. The biochip's unique design minimizes mechanical stress, reducing the likelihood of damage and prolonging the lifespan of the media.

Energy Efficiency

With a specific gravity of approximately 0.95 kg/l (without biofilm), the Mutag BioChip™ remains suspended in the wastewater with minimal energy input. This reduces the overall operational costs associated with wastewater treatment, making it an economical choice for both municipal and industrial applications.

Mutag Biochip's Advantages

High Contaminant Removal Rates: Thanks to its large surface area and efficient biofilm formation, the Mutag BioChip™ excels in the removal of organic pollutants and nitrogen compounds, providing high treatment efficiency and process stability.

Low Maintenance: The durable design of the mutag biochip 30 ensures long-lasting performance with minimal maintenance, reducing the need for frequent replacements and lowering overall operational costs.

Cost-Effective: The Mutag BioChip 30 offers a favorable price-to-surface area ratio, making it a cost-effective solution for large-scale wastewater treatment projects.

Specification

Product Name | Mbbr biochip |

Surface area | >5,500m²/m³ |

Weight(Net) | 135kg/m3±3% |

Packing numbers | 340000pcs/cbm |

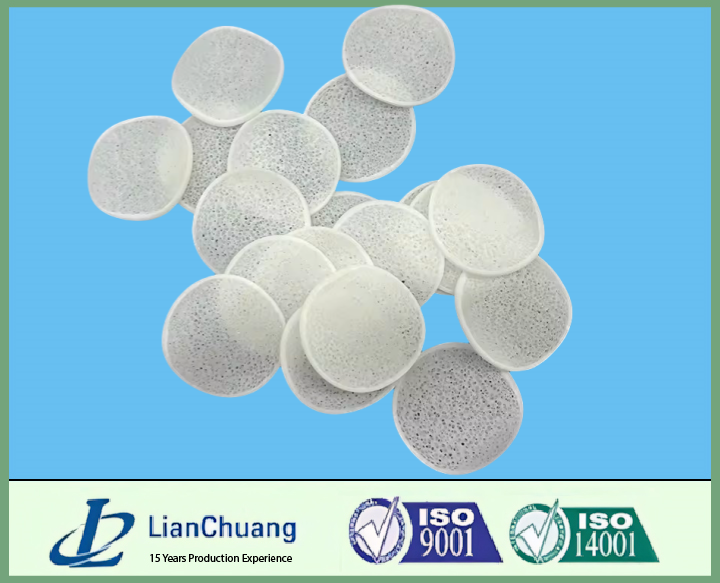

Color | White |

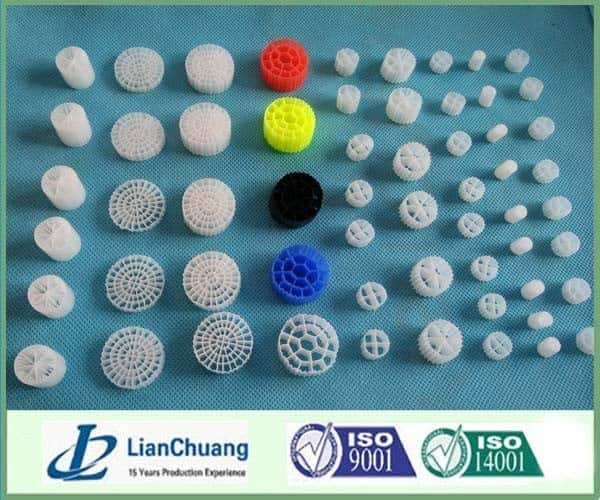

Shape | Round, with outer ring |

Material | Virgin HDPE |

Diameter | 30mm |

Thickness | 1-1.05mm |

Density | 0.95g/cmm³ |

Package: | Woven bag |

Small Packaging | 0.1m³/Bag |

Packing numbers | 340000pcs/cbm |

Applications

The Mutag BioChip mbbr media is versatile and can be used across a wide range of wastewater treatment applications, including:

Municipal Wastewater Treatment: Ideal for treating sewage in urban areas, ensuring compliance with environmental regulations by effectively removing organic matter (BOD, COD) and nitrogen compounds.

Industrial Wastewater Treatment: Suitable for treating wastewater from various industries, including metallurgy, food and beverage processing, and electronics manufacturing, where high organic loads and specific contaminants need to be removed.

Recirculating Aquaculture Systems (RAS): Perfect for reducing nitrogen levels to safe concentrations for aquatic life, ensuring optimal water quality in fish farming operations

Packaging and Delivery

Packaging: The Mutag BioChip™ is securely packed in plastic bags to protect the media during transit.

Supply Capacity: Available with an annual production capacity of up to 10 million cubic meters, ensuring consistent supply for large and ongoing projects.

Delivery: Shipped from Shanghai, China, with customizable options for order size and delivery schedule to meet specific project needs.