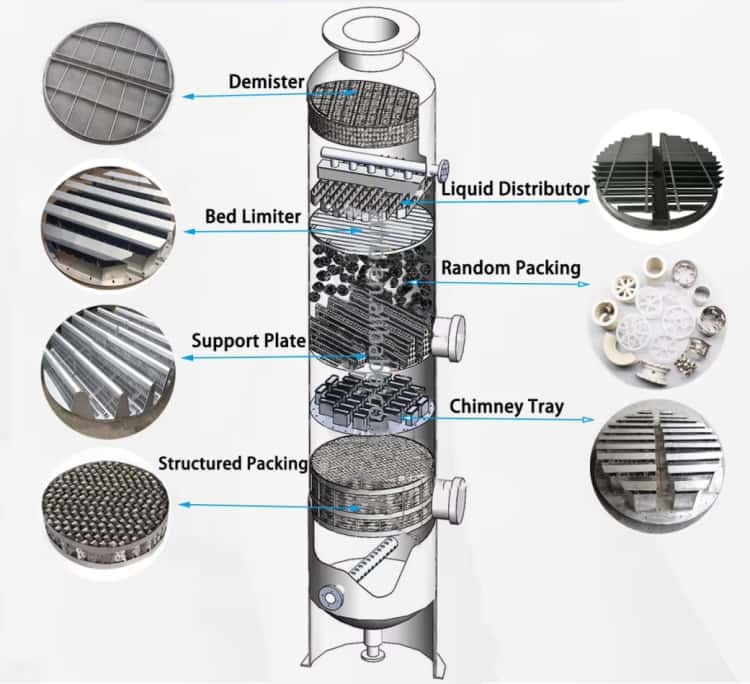

Wire mesh demister is a widely used gas-liquid separation device. It improves gas quality, protects downstream equipment, and stabilizes process performance. Many operators install a wire mesh demister near the top section of a tower, separator, or scrubber to capture entrained liquid and deliver cleaner gas. This approach enhances reliability, reduces fouling, and lowers operating costs.

Because it is mounted inside process equipment, some users call it a demister pad in vessel. In practice, a wire mesh demister offers simple construction, high efficiency, and easy maintenance, making it a dependable choice for new builds and retrofits.

How the Wire Mesh Demister Works

Wire mesh demister operates on direct interception and coalescence. Gas carrying fine droplets passes through a dense mesh matrix. Droplets collide with wires, adhere to the filaments, and merge into larger drops. As drops grow, gravity overcomes drag and the liquid falls back to the liquid surface or a drain tray. The result is effective separation with minimal pressure drop.

1. Gas enters the vessel and rises through the mesh bed.

2. Fine droplets impact wire surfaces and stick to the fibers.

3. Captured droplets coalesce into larger drops within the mesh.

4. Large drops detach and drain downward under gravity.

This continuous cycle allows a wire mesh demister to remove droplets efficiently while keeping energy consumption low. The stable flow pattern also protects compressors, exchangers, and downstream catalysts.

Design and Structure

Wire mesh demister consists of multiple layers of woven or knitted wires packed into a support frame. The structure maximizes surface area and creates tortuous flow paths for droplet capture. Typical removal targets include droplets larger than 3–5 microns, with configurations tuned for velocity and fluid properties.

1. Mesh density and thickness are selected to balance efficiency and pressure drop.

2. Bed geometry is customized to vessel diameter and nozzle locations.

3. Support grids and hold-down devices prevent shifting and vibration.

4. Drain paths ensure rapid liquid return and avoid re-entrainment.

The structure, sometimes referred to as demister mesh, promotes uniform distribution and stable operation across a wide turndown range.

Key Materials Used

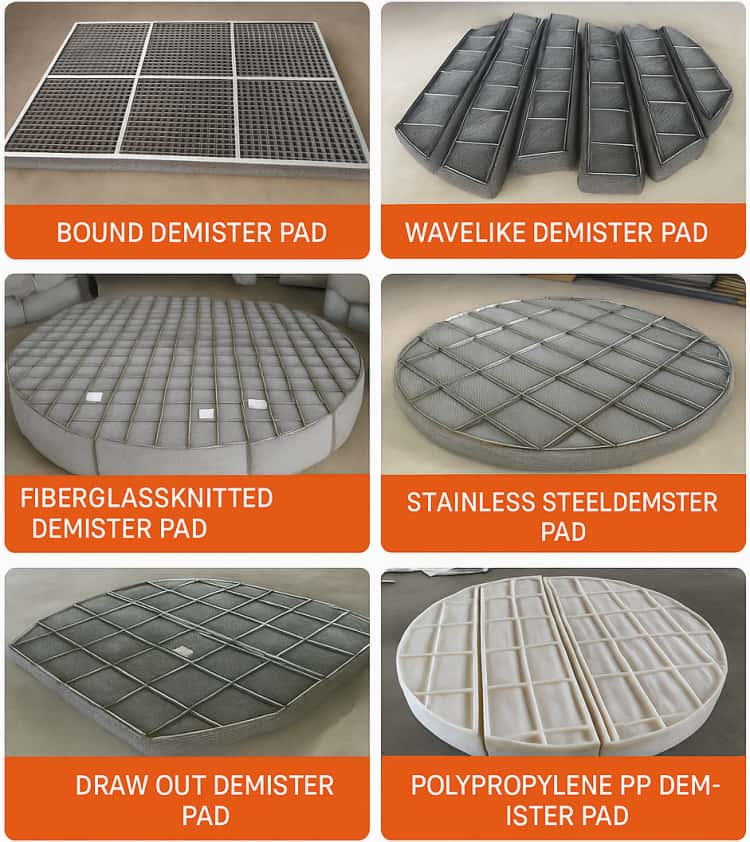

Material selection determines longevity, corrosion resistance, and temperature limits. A wire mesh demister can be built from metals or plastics to match process chemistry.

1. Stainless steel 304, 304L, 316, and 316L provide robust corrosion resistance for general services.

2. Nickel-based alloys such as Monel and Hastelloy withstand acidic media and high temperatures.

3. Titanium and titanium alloys resist chloride attack and suit seawater or offshore duties.

4. Galvanized carbon steel is economical for moderate and non-aggressive conditions.

5. Plastics like PP and PTFE tolerate strong acids and alkalis in chemical processes.

Features and Benefits

Wire mesh demister provides reliable separation performance with low lifecycle cost. It fits both new installations and upgrades where space is limited.

1. High efficiency with removal rates typically exceeding 98% for target droplet sizes.

2. Low pressure drop to maintain throughput and reduce blower or compressor power.

3. Flexible design for different tower sizes, vapor loads, and turndown needs.

4. Easy maintenance thanks to lightweight sections that are simple to handle.

5. Strong corrosion resistance when built from properly selected materials.

Applications Across Industries

Wire mesh demister supports clean gas production and reduces carryover in many sectors. It also helps meet emissions and product quality targets.

1. Distillation and absorption towers improve separation by limiting entrainment.

2. Petroleum refining and chemical processing protect heat exchangers and compressors.

3. Natural gas systems aid dehydration and acid gas treatment to stabilize downstream units.

4. Environmental control units reduce emissions and improve scrubber performance.

5. General industrial services enhance reliability in diverse gas-liquid operations.

For operators, a vessel demister improves uptime, reduces cleaning frequency, and safeguards catalysts and adsorbents used downstream.

Customization for Specific Needs

Each process has unique constraints. A wire mesh demister is tailored to operating pressure, temperature, vapor velocity, and chemistry to reach target efficiencies.

1. Dimensions and shapes match vessel internals, trays, and nozzle positions.

2. Mesh density, wire diameter, and bed thickness align with droplet spectrum and gas load.

3. Modular segments simplify installation in tight manways and constrained spaces.

4. Material upgrades extend service life in corrosive or high-temperature environments.

When ordered as a vessel demister pad, engineering teams supply drawings, load limits, and pressure-drop estimates to ensure smooth integration.

Installation and Maintenance Tips

Proper installation keeps a wire mesh demister performing at design efficiency. Routine checks maintain low pressure drop and prevent re-entrainment.

1. Level the support grid and confirm full contact with the vessel seat.

2. Verify that segments fit snugly with no bypass gaps along the shell.

3. Install hold-downs to prevent uplift during turndown or surges.

4. Inspect periodically for fouling; clean with water, steam, or solvent per material limits.

Conclusion

Wire mesh demister is a proven, cost-effective solution for gas-liquid separation. By integrating a vessel demister and selecting the right materials and geometry, plants achieve cleaner gas, lower energy use, and better protection for downstream equipment. Whether specified as a vessel demister pad or adapted to an existing tower, this simple device delivers consistent results with minimal complexity.