Cooling tower fills are critical components in cooling towers, maximizing the contact area between water and air to enhance heat transfer. The price of cooling tower fills is influenced by various factors, including material type, design, manufacturing quality, and market dynamics. This article explores the key factors affecting cooling tower fill price, current market trends, and important considerations for buyers.

Factors Affecting Cooling Tower Fill Price

1. Material Type

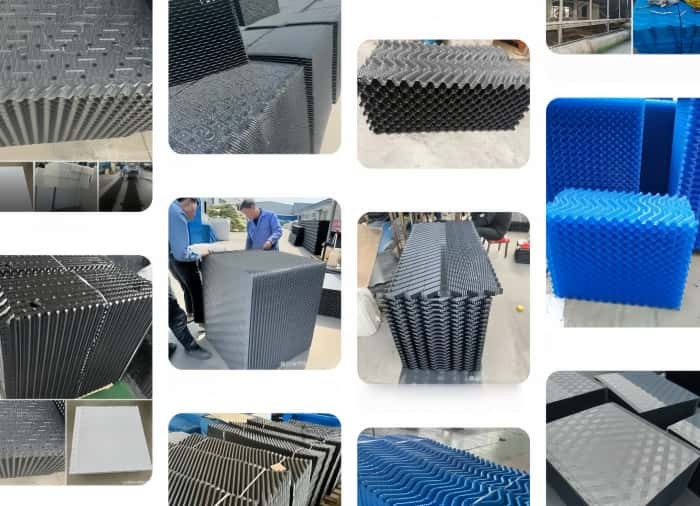

Cooling tower fills are typically made of PVC (Polyvinyl Chloride), PP (Polypropylene), or other specialized plastics. Material selection has a significant impact on cost:

- PVC Fills: PVC fills are the most cost-effective choice due to their affordability and durability. Prices generally range from $0.30 to $2 per square foot, depending on thickness and quality.

- PP Fills: These fills offer higher temperature and chemical resistance but are more expensive than PVC.

- Specialized Materials: High-performance fills with UV resistance or enhanced thermal efficiency may exceed $3 per square foot.

2. Fill Design and Configuration

The design, such as crossflow or counterflow configuration, affects pricing:

- Film Fills: Thin, closely spaced sheets offer high efficiency but come at a higher cost, typically 10–20% more expensive than splash fills.

- Splash Fills: Less expensive but lower efficiency, suitable for applications with lower heat loads, usually 20–30% cheaper than film fills.

3. Manufacturing and Quality Standards

High-quality fills are priced higher due to precision manufacturing and compliance with industry standards (e.g., CTI or ASHRAE). Additional costs may include:

- Antimicrobial coatings to prevent biological growth.

- Fire-retardant properties to meet safety requirements.

- Custom fills designed for specific cooling tower models, which may increase the price by 15–25%.

4. Market and Regional Factors

Prices vary by region due to differences in labor costs, transportation, and local demand:

- In North America and Europe, strict quality standards and higher labor costs lead to higher prices.

- In Asia, particularly in China and India, large-scale production and competition result in lower prices. For example, PVC fill prices in Asia can be as low as $0.30 per square foot.

5. Purchase Volume

Bulk purchases can significantly reduce unit costs. Suppliers often offer 10–20% discounts for orders exceeding 10,000 square feet.

6. Trade Terms

In export trade, cooling tower fill prices vary depending on trade terms:

- EXW (Ex Works): Buyer bears all transportation and insurance costs; lowest price but higher responsibility and risk for the buyer.

- FOB (Free On Board): Seller covers cost to load on the ship; buyer handles sea freight and insurance; slightly higher than EXW.

- CIF (Cost, Insurance, Freight): Seller covers freight and insurance; higher price than FOB, convenient for buyers.

- DDP (Delivered Duty Paid): Seller bears all costs, including shipping, insurance, and destination duties; highest price but most convenient for buyers.

Price differences mainly come from which party bears transport, insurance, and customs duties. Buyers can choose terms based on logistics capability and cost management needs.

Current Market Trends

- Rising Raw Material Costs: Global supply chain disruptions and higher PVC resin costs have increased prices by 5–10% over the past year.

- Increased Demand for Energy Efficiency: Growing emphasis on energy-efficient cooling systems drives demand for high-performance film fills, pushing prices higher.

- Sustainability Focus: Eco-friendly and recyclable fills are gaining popularity but cost 15–30% more than standard fills.

- Technological Innovations: Hybrid fills combining film and splash designs are emerging, priced at $2.50–$4 per square foot.

How to Choose the Right Cooling Tower Fill

- Assess Water Quality: For water with high suspended solids, splash fills may reduce maintenance costs despite higher unit price.

- Check System Compatibility: Ensure fill dimensions match the cooling tower design to maintain performance.

- Balance Price and Longevity: Investing in high-quality PP or fire-retardant PVC can save costs in the long term.

- Consider Bulk Purchases: Larger orders often result in better unit pricing.

Buyer Considerations

- Application Needs: Choose fill type according to operating conditions, such as temperature and water quality.

- Total Cost of Ownership: Efficient fills can reduce long-term energy and maintenance expenses, even if the initial cost is higher.

- Supplier Reputation: Select certified and reliable suppliers to ensure quality and durability.

- Installation Costs: Installation expenses vary by complexity, ranging from $0.20 to $0.50 per square foot.

Conclusion

Cooling tower fill prices are influenced by material choice, design specifications, manufacturing standards, purchase volume, and trade terms, as well as market dynamics. Prices vary by region and application. Buyers should weigh initial costs against long-term performance and efficiency to make informed decisions. For the latest prices and supplier options, direct consultation with suppliers is recommended.