The aero air membrane fine bubble tube diffuser stands out for its high oxygen transfer rate and energy-saving features. It is a core component in modern water treatment technology. In wastewater treatment, aeration systems often account for 30% to 70% of total energy consumption. The aero air membrane fine bubble tube diffuser for wastewater treatment produces small bubbles with diameters typically 1-3 mm. This greatly improves oxygen utilization. It helps reduce operating costs and enhance water quality.

The aero air membrane fine bubble tube diffuser for wastewater treatment belongs to the fine bubble diffuser family. Compared to coarse bubble diffusers, it focuses more on oxygen transfer rather than just mixing and stirring. Coarse bubble diffusers create larger bubbles over 3 mm in diameter. They suit scenarios needing strong mixing. Fine bubble diffusers use small bubbles to extend gas-liquid contact time. This achieves higher standard oxygen transfer efficiency (SOTE), usually over 2%.

This article provides a detailed introduction to the aero air membrane fine bubble tube diffuser for wastewater treatment. It covers its working principles, advantages, types, applications, installation, maintenance, and technical specifications. Readers will gain a comprehensive understanding of this tube diffuser.

Working Principle

The core of the aero air membrane fine bubble tube diffuser for wastewater treatment lies in its membrane structure and bubble generation mechanism. It is typically made of a ceramic or plastic cylinder wrapped with EPDM (ethylene propylene diene monomer) rubber membrane or other elastic materials.

When compressed air enters the cylinder, air pressure expands the micro-pores on the membrane. These pores are usually 0.75-3 mm in diameter. This releases fine bubbles. These bubbles are small in diameter and rise slowly. They have longer contact time with water. This enhances oxygen dissolution efficiency from bubbles to water.

According to the double-film theory, oxygen transfer rate (OTR) depends on the liquid-side mass transfer coefficient (Kₗa), saturated dissolved oxygen concentration (Cₛ), and the difference with actual dissolved oxygen concentration (C), plus water volume (V).

The specific process is as follows: Compressed air from blowers travels through a pipeline network. This includes headers, drop pipes, and distribution pipes. It reaches the bottom of the tube diffuser.

Air is released through porous membranes or ceramic structures. This forms fine bubbles. During ascent, oxygen transfer occurs. Small bubbles have a higher surface area-to-volume ratio. This leads to higher oxygen transfer efficiency (OTE).

Wastewater characteristics affect the alpha factor (usually 0.3-1.0). This reflects pollutant inhibition on oxygen transfer. But fine bubble designs can improve alpha by extending mean cell residence time (MCRT).

Compared to coarse bubble diffusers, fine bubble systems need only half the air to produce over twice the oxygen mass.

The tube design ensures even bubble distribution. It creates a consistent bubble curtain along the entire cylinder length. This avoids local blockages or uneven aeration.

This self-closing pore structure seals micro-pores when no pressure is applied. It prevents sludge or pollutants from entering. This enhances system stability.

Structural Design

The aero air membrane fine bubble tube diffuser for wastewater treatment usually consists of three parts:

1. Membrane: Typically made of high-quality elastic materials like EPDM (ethylene propylene diene monomer), PTFE-coated EPDM, silicone, or polyurethane. The membrane determines bubble size, chemical resistance, and anti-fouling performance.

2. Support Tube: The inner tube provides mechanical support and gas channels for the membrane. Modern structures often use slotted or ribbed support tubes. This improves airflow distribution and reduces membrane stress concentration.

3. Connection Fittings: The tube diffuser can be installed via different interfaces like threaded joints, saddle mounts, or flange fixings. This adapts to various operating conditions.

Advantages

The aero air membrane fine bubble tube diffuser for wastewater treatment shows several significant advantages in practical applications. It makes this tube diffuser a top choice in wastewater treatment.

Efficient Oxygen Transfer: Small bubbles provide larger surface area. This raises dissolved oxygen levels. It supports rapid microbial degradation of organic matter. SOTE can reach over 2%. This is more than twice as efficient as coarse bubble systems.

Energy-Saving Effect: It requires less air volume and blower pressure. This reduces energy consumption. Aeration energy savings can significantly lower overall operating costs.

Durability and Stability: Materials like EPDM have good chemical stability. They lack plasticizers. They resist hardening, brittleness, or aging. They are resistant to acids, alkalis, and chemical corrosion. They suit various water quality environments.

Low Maintenance Needs: It is not prone to clogging. Installation and removal are easy. This reduces downtime. Some models with PTFE-coated membranes have strong anti-fouling ability. This further lowers cleaning frequency.

Uniform Mixing: Even bubble curtains promote wastewater mixing. They prevent sludge deposition. This improves treatment consistency.

Environmentally Friendly: It improves effluent water quality. It ensures compliance with environmental regulations. It applies to complex conditions like high salinity or acidity/alkalinity.

Overall, compared to mechanical aeration, fine bubble systems consume less energy for the same oxygen transfer. They offer better dissolved oxygen control.

In addition, the aero air membrane fine bubble tube diffuser for wastewater treatment can integrate with smart monitoring systems. This allows real-time adjustments for optimal performance in varying wastewater loads.

Types

The aero air membrane fine bubble tube diffuser for wastewater treatment is classified by diameter, length, membrane material, perforation details, and connection methods.

Main types include:

By Diameter and Length: Common specifications like 63mm x 1000mm, 90mm x 1000mm, 90mm x 2000mm. Perforated lengths can be 500mm, 750mm, or 1000mm.

By Membrane Material:

EPDM Membrane: High elasticity (elongation up to 700%). Anti-static and anti-fouling. Suitable for standard wastewater treatment.

PTFE-Coated Membrane: High anti-fouling and chemical resistance. Ideal for solvent or grease environments. It reduces long-term power costs.

Silicone Membrane: Heat-resistant up to 315°C. Suitable for ozone or high-temperature systems.

Polyurethane (PU) Membrane: High strength. Suitable for industrial durability needs.

Viton® Membrane: High chemical resistance. For high-end budget applications.

By Connection Method: C-type saddle connection, U-type clip connection, NPT threaded connection (3/4" or 1"). Some models install directly with U-bolts without extra joints.

Other variants include spherical or plate types. But tube diffusers are known for large surface area and uniform bubble distribution.

For specialized needs, custom tube diffuser designs can incorporate hybrid materials to enhance longevity in harsh industrial settings.

Application Areas

The aero air membrane fine bubble tube diffuser for wastewater treatment is widely used in various water treatment scenarios.

Wastewater Treatment: In activated sludge systems, SBR (sequencing batch reactor), and MBBR (moving bed biofilm reactor). It provides oxygen for carbon oxidation and nitrification. This reduces BOD and COD.

Industrial Wastewater: Suitable for food and beverage, pharmaceutical, chemical, and paper industries. It handles high-strength wastewater and toxic compounds.

Aquaculture: In fish ponds and breeding pools. It maintains dissolved oxygen. It controls ammonia nitrogen. It promotes waste decomposition.

Lake and River Restoration: Enhances self-purification capacity. Removes nutrients. Improves water quality.

Landfill Leachate Treatment: Promotes organic pollutant degradation. Reduces pollutant emissions.

Aerobic Digesters: Stabilizes sludge. Reduces odors and treatment costs.

Its versatility makes this tube diffuser suitable for systems from municipal to industrial scales.

Material Types and Optional Solutions

The membrane materials for the aero air membrane fine bubble tube diffuser for wastewater treatment are diverse. Each has unique advantages.

EPDM (Ethylene Propylene Diene Monomer): Excellent elasticity and durability. Suitable for general municipal and industrial wastewater.

PTFE-Coated EPDM: Offers superior anti-fouling and chemical resistance. Ideal for long-term stable operation. It reduces cleaning frequency.

Silicone: High flexibility, smooth surface, strong chemical inertness. Suitable for high-purity or special conditions.

Polyurethane: High mechanical strength and wear resistance. Fits applications with large load fluctuations or high solids content.

Performance and Design Considerations

When selecting the aero air membrane fine bubble tube diffuser for wastewater treatment, consider several factors.

Bubble Diameter and Distribution Uniformity: Ensure even aeration across the system.

Operating Air Volume Range and Pressure Drop: Optimize for energy efficiency.

Membrane Material Compatibility with Wastewater Medium: Match chemical properties to avoid degradation.

Pool Depth and Diffuser Layout: Adapt to site-specific hydraulics.

Cleaning Maintenance Frequency and Operability: Choose designs that minimize downtime.

Proper design ensures uniform gas distribution. It achieves minimal energy consumption. It maximizes oxygen transfer efficiency.

Advanced computational fluid dynamics (CFD) modeling can be used in design phases. This predicts performance and identifies potential issues before installation.

Installation Guide

Installing the aero air membrane fine bubble tube diffuser for wastewater treatment requires considering system design and pipe types.

Position: Place at the bottom or side of the aeration tank. Ensure even air distribution. Maintain proper angles. Avoid high-flow areas to prevent bubble loss.

Connection: For PVC pipes, use saddles or U-clips. For stainless steel pipes, weld joints. Common connections include ISO G3/4" F threads or NPT joints.

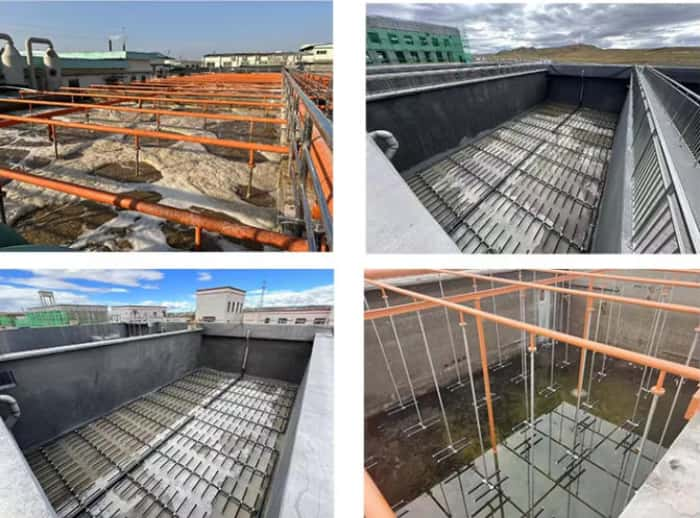

Grid Layout: Install in a grid pattern at the reactor bottom. Connect via drop pipes to distribution pipes. Use stainless steel anchors to resist buoyancy and hydrodynamic forces. Ensure horizontal installation.

Additional Considerations: Install purge systems to remove moisture. Add flow meters and control valves to monitor air distribution. Pre-sale design services may include 3D simulations and fluid dynamics modeling.

Tube diffuser installation costs are low. They can be floating or fixed. Sizes are customizable.

Maintenance Recommendations

Regular maintenance is key to ensuring performance of the aero air membrane fine bubble tube diffuser for wastewater treatment.

Inspection: At least once a year. Check for dirt, wear, or damage.

Cleaning: Physical cleaning uses medium-pressure soft brushes (under 60 psig). Chemical cleaning injects low-strength acids to remove mineral deposits. Air bumping (5-10 minutes weekly with increased airflow) reduces biofilms.

Replacement: Replace membranes every 3-5 years, depending on conditions. Check seals to prevent blockages.

Testing: Use ASCE standards for clean water SOTE tests or in-process off-gas tests to evaluate efficiency.

Durable materials reduce maintenance frequency. But tube diffusers may require more maintenance than other types.

Technical Specifications

Typical specifications for the aero air membrane fine bubble tube diffuser for wastewater treatment include:

Bubble Diameter: 1-3 mm (usually under 3 mm).

Perforation Size: 1.0-1.5 mm.

Dimensions: Diameter 63mm or 90mm; Length 1000mm or 2000mm.

Materials: EPDM, PTFE, silicone, PU, etc.

Working Pressure: 0.2-0.4 MPa; Pipe pressure resistance at least 25 psig, temperature resistance 250-300°F.

Efficiency: SOTE over 2%; SAE produces over twice the oxygen mass.

Mixing Requirements: 0.05-0.09 scfm per square foot.

Conclusion

The aero air membrane fine bubble tube diffuser for wastewater treatment plays an indispensable role in water treatment. It excels in efficiency, energy savings, and versatility.

By optimizing oxygen transfer, it enhances treatment efficiency. It reduces environmental impact.

With technological advancements like advanced membrane materials, this tube diffuser will continue to drive sustainable water resource management.

For practical applications, consult professional manufacturers based on specific needs. This ensures optimal performance.

Explore options like the fine bubble tube diffuser for standard needs. Consider the membrane tube diffuser for enhanced durability. The aero tube diffuser offers specialized aeration. Use the air diffuser tube in compact systems. The tube air diffuser provides flexible installation.