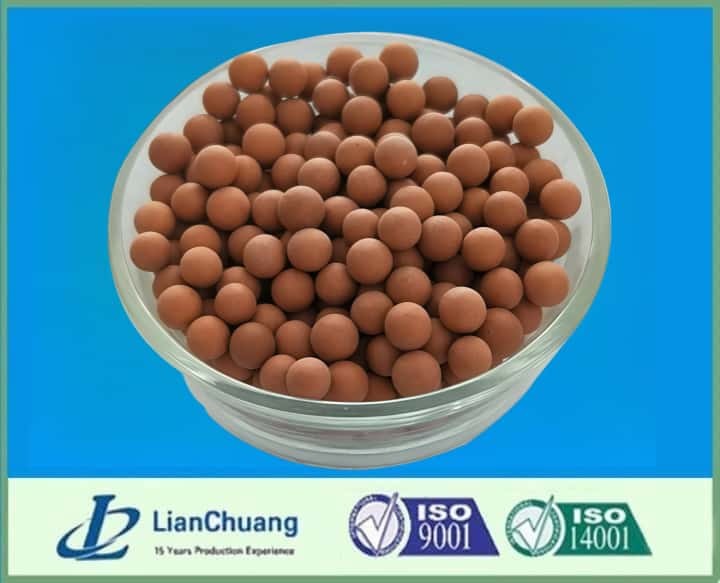

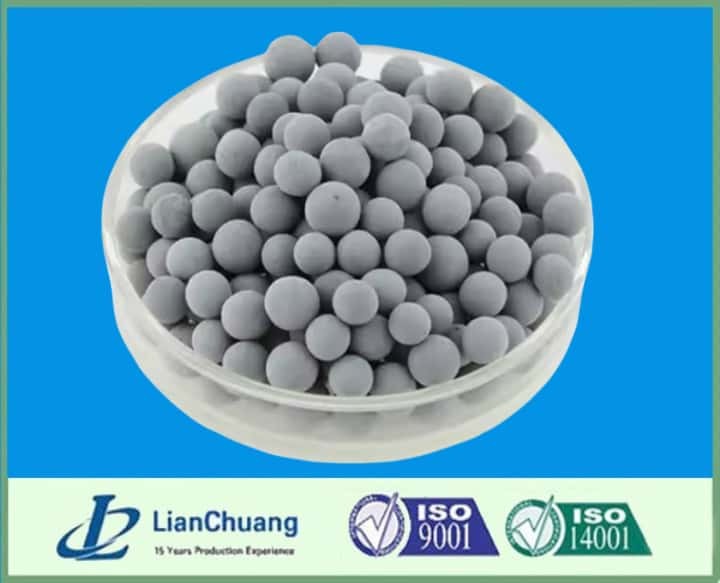

Product Description

Zeolite ceramic balls are made from high-quality zeolite minerals, bauxite, and multifunctional mineral materials. These materials are processed in high-temperature furnaces to create durable ceramic balls that offer superior adsorption, purification, and catalytic properties. Zeolite ceramic balls are widely used in industries like air purification, water filtration, and automotive exhaust treatment.

Understanding Zeolite and Its Properties

Zeolite is a type of hydrated aluminosilicate mineral that forms through the diagenesis of volcanic ash during the Cenozoic era. This natural mineral is known for its porous nature, which is perfect for filtration applications. Zeolite comes in two forms: natural and synthetic, with pore sizes typically ranging from 3Å to 8Å.

zeolite balls have remarkable physical adsorption capacities (90%-95%) and outstanding cation exchange abilities, exchanging between 70 to 160 milligrams of ions per 100 grams. This feature makes Zeolite Balls ideal for a wide range of filtration and purification processes, as they can absorb and release substances, even up to 20 times their own weight.

Key Features of Zeolite Balls

- Superior Adsorption and Purification: Zeolite balls are highly effective at adsorbing moisture and purifying air and water, making them suitable for various filtration systems.

- High Ion Exchange Capacity: These ceramic balls excel in water softening, fluoride removal, and wastewater treatment. Their ion exchange properties make them effective in removing heavy metals and desalination.

- Durable and Long-lasting: With a bulk density of 0.60-0.65 g/ml and minimal wear (0.3-0.6%), zeolite balls are built to last, even under harsh conditions.

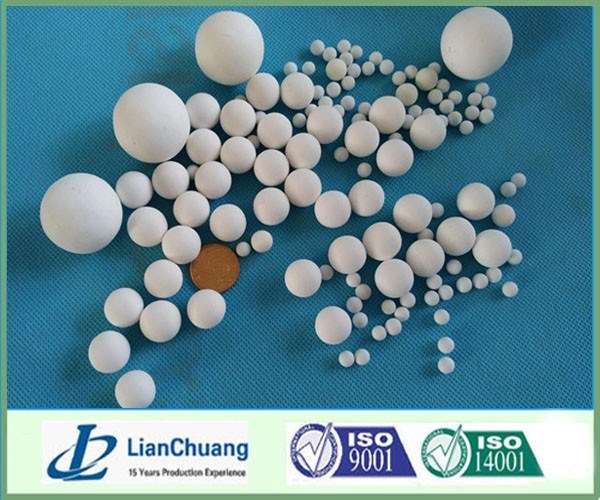

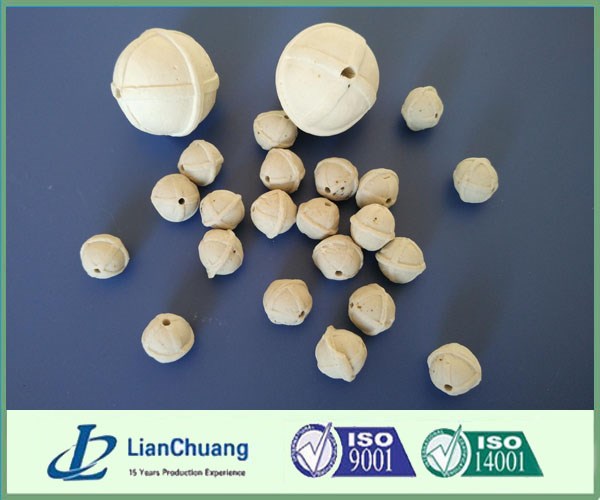

Product Specifications

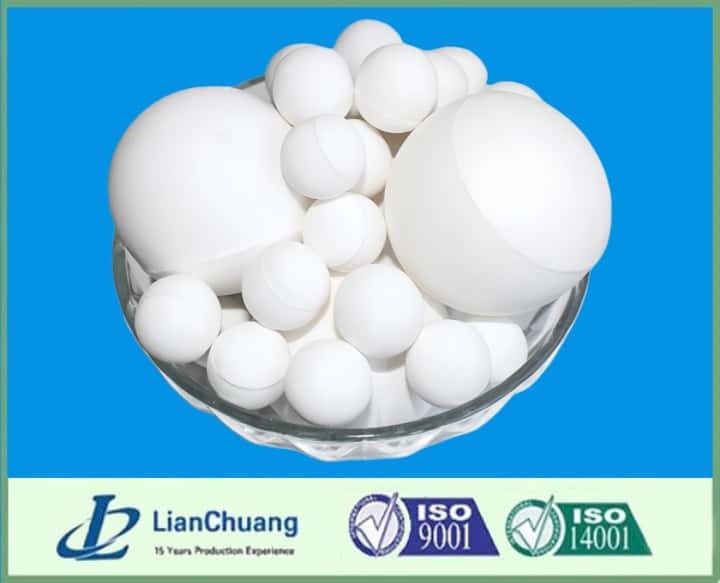

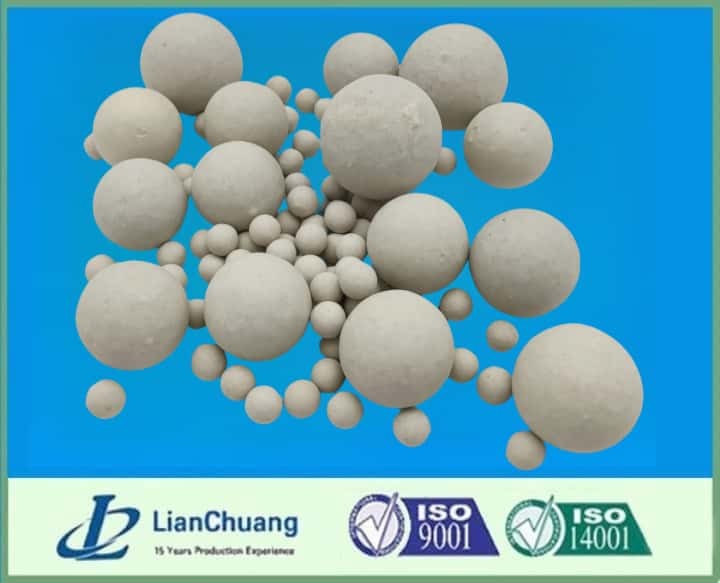

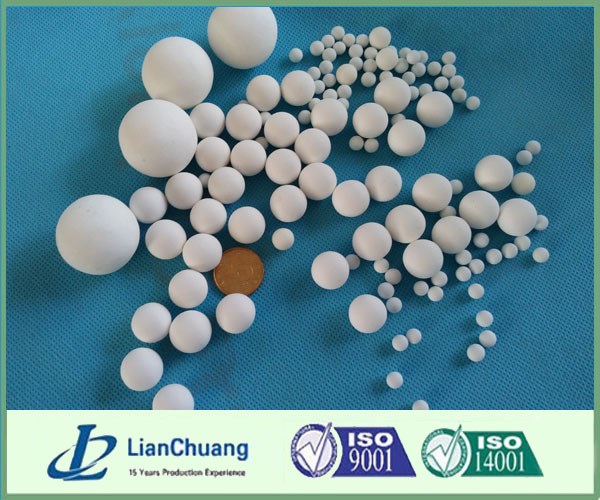

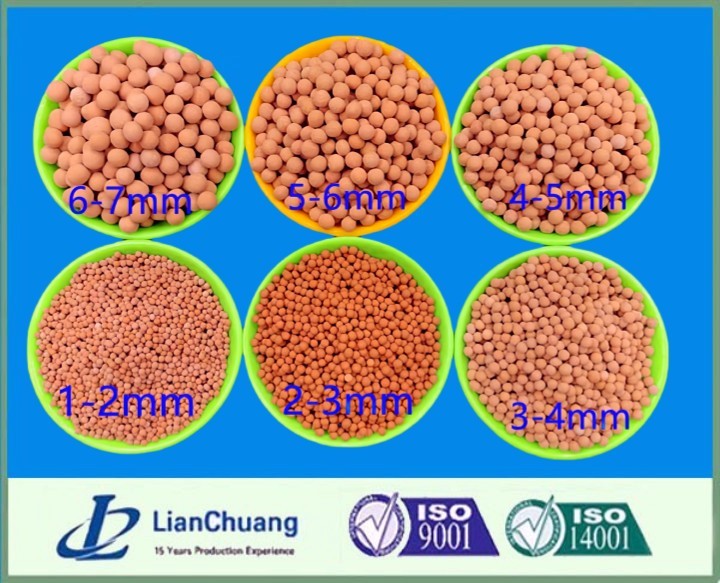

Item Standard Product Name Zeolite ceramic ball Appearance Light yellow color spherical balls Size Distribution Diameter 2-30mm or customized Bulk Density (g/ml) 0.60-0.65 Water Absorption (%) 20-21 Wear Ability (%) 0.3-0.6 Application 1. Drying agent for natural gas and absorbent for paraffin separation;

2. Absorption separation agent, molecular sieve deodorant;

3. Water softening, fluorine removal, wastewater and sewage treatment, heavy metal removal, desalination

Applications of Zeolite Balls

- Air and Gas Purification: Zeolite balls are used as drying agents for natural gas and as absorbents for paraffin separation. They help in the purification of gases by trapping unwanted molecules.

- Water Softening and Filtration: Zeolite ceramic balls are ideal for water softening applications, removing fluoride, and treating wastewater. These balls efficiently remove harmful contaminants, providing cleaner, safer water.

- Heavy Metal Removal: Zeolite balls are effective in the removal of heavy metals from water and sewage. Their ion-exchange properties allow them to bind with toxic metals, making them essential in industrial wastewater treatment.

- Deodorization and Separation: Zeolite balls are used as molecular sieves and deodorants, helping to purify gases and liquids by absorbing unwanted molecules and odors.

Key Benefits of Zeolite Balls

- Moisture Absorption: The high water absorption rate (20-21%) ensures Zeolite balls perform efficiently in drying and dehumidifying applications.

- Ion-Exchange Properties: They effectively soften water, remove fluoride, and purify wastewater by removing heavy metals and other contaminants.

- Durability: Zeolite balls are highly durable and resistant to wear, providing long-term reliability in water filtration and gas purification systems.

Zeolite Balls offer a versatile and effective solution for many filtration needs. Whether you are dealing with nitrogen removal, water purification, or air filtration, these ceramic balls provide optimal results. Their unique adsorption and ion-exchange features make them a preferred choice for industries requiring efficient and reliable filtration.

The combination of their physical and chemical properties allows Zeolite ceramic balls to perform exceptionally well in various applications, from wastewater treatment to gas purification. Their capacity to handle a wide range of substances, including nitrogen, makes them invaluable in many industrial processes.

With their excellent moisture absorption, ion-exchange capacity, and durability, Zeolite ceramic balls provide superior filtration for nitrogen removal, wastewater treatment, and air purification. These ceramic balls offer an efficient, cost-effective solution for a variety of applications, ensuring clean air, water, and gas systems.