Product Description

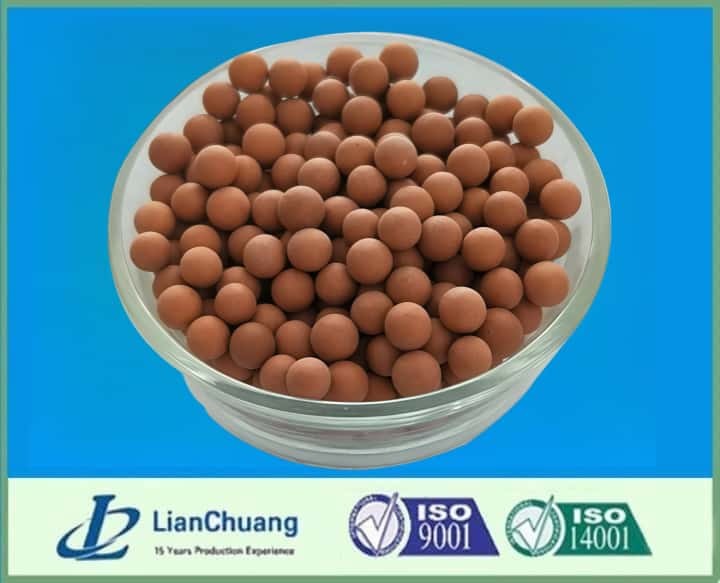

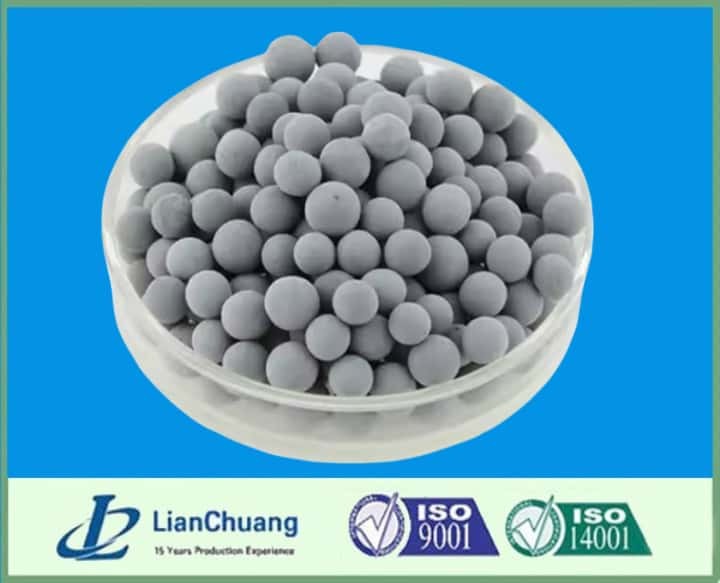

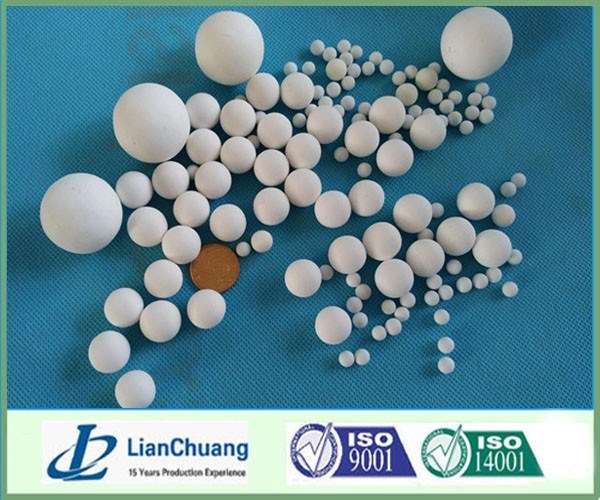

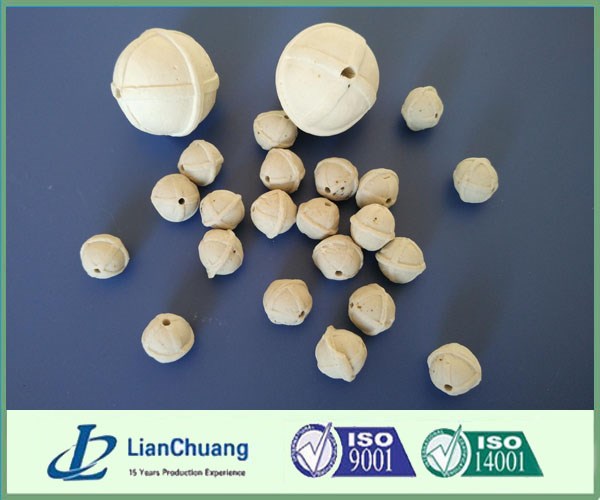

The Inert Catalyst Support porcelain balls are essential components widely used in chemical reactors, gas processing units, water treatment facilities, and petrochemical systems. These ceramic balls are made from high-purity silicate porcelain with an aluminum oxide content ranging between 17% and 26%, offering superior thermal stability, mechanical strength, and chemical resistance.

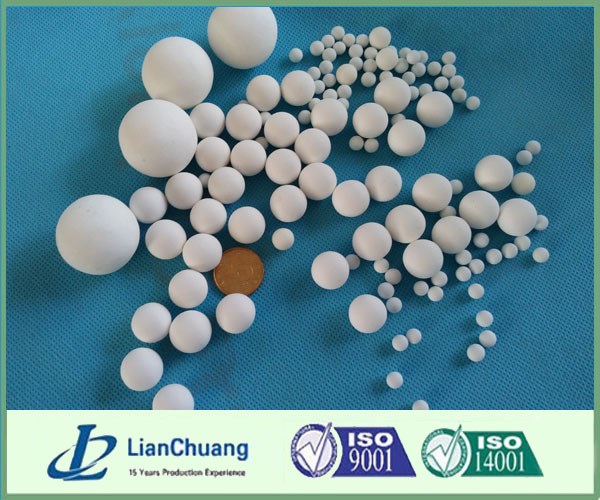

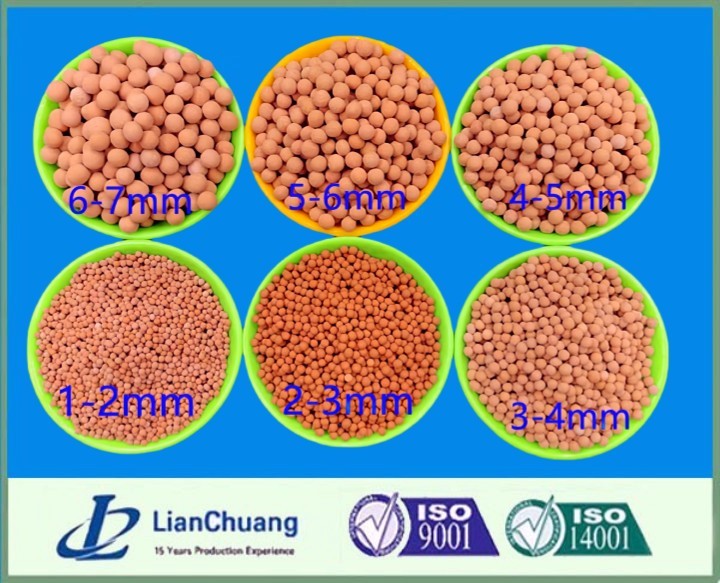

Typically used as bed support media, these balls are placed in layers of varying sizes at the top and bottom of reactor vessels. This design provides uniform support to catalyst beds, prevents media breakthrough, and ensures smooth flow dynamics within the reaction system.

Manufactured with solid-pressed silicate porcelain, these balls exhibit excellent resistance to acids, alkalis, thermal shock, and certain organic solvents—making them ideal for demanding environments and all types of catalyst support applications.

Key Features:

- High Chemical Stability: Resistant to most acids, alkalis, and corrosive environments, ensuring reliable long-term performance.

- Thermal Resistance: Capable of withstanding high operational temperatures without deforming or cracking.

- Low Reactivity: Chemically inert material prevents unwanted reactions, safeguarding catalyst and system integrity.

- Optimal Mechanical Support: Provides robust and uniform support for catalyst beds, promoting efficient gas and liquid distribution during reactions.

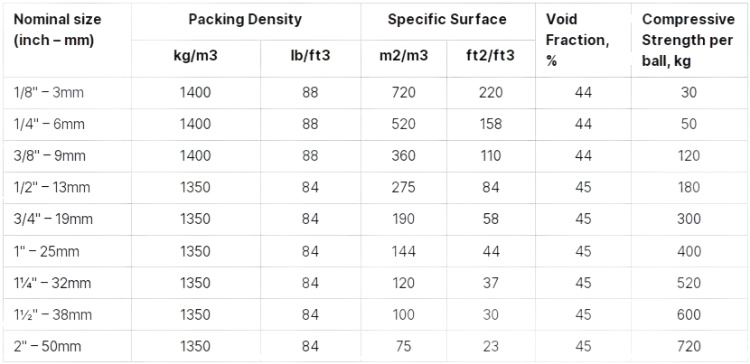

- Multiple Sizes Available: Offered in standard sizes ranging from 3 mm to 50 mm in diameter, including 1/8", 1/4", 3/8", 1/2", 3/4", 1", 1¼", 1½", and 2". Custom sizes and ceramic compositions are also available upon request.

Specifications of 23% Alumina Ceramic Ball:

Typical Chemical Composition (23% Alumina Ceramic Ball):

| Component | Content |

|---|---|

| Al₂O₃ + SiO₂ | > 92% |

| Al₂O₃ | 23–26% |

| SiO₂ | 68–72% |

| Fe₂O₃ | 0.4–0.8% |

| CaO | 0.6–0.9% |

| MgO | 0.6–1.2% |

| K₂O + Na₂O | < 3.5% |

| Others | < 1% |

Applications:

- Catalytic Reactors: Used to support and disperse catalyst particles, improving contact efficiency between gas and liquid phases.

- Water Treatment Systems: Function as mechanical supports in filtration systems, helping maintain flow stability and filter media performance.

- Gas Absorption and Separation Units: Enhance the efficiency of scrubbers, absorbers, and separators across chemical and petrochemical industries.