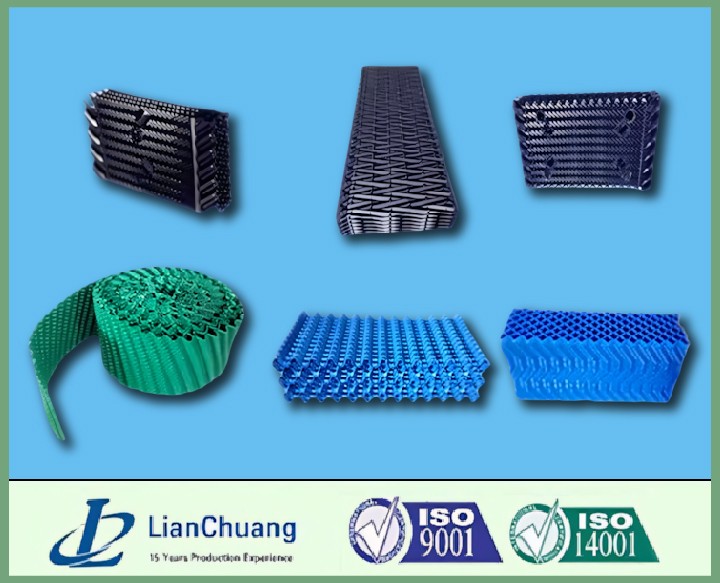

Product Description

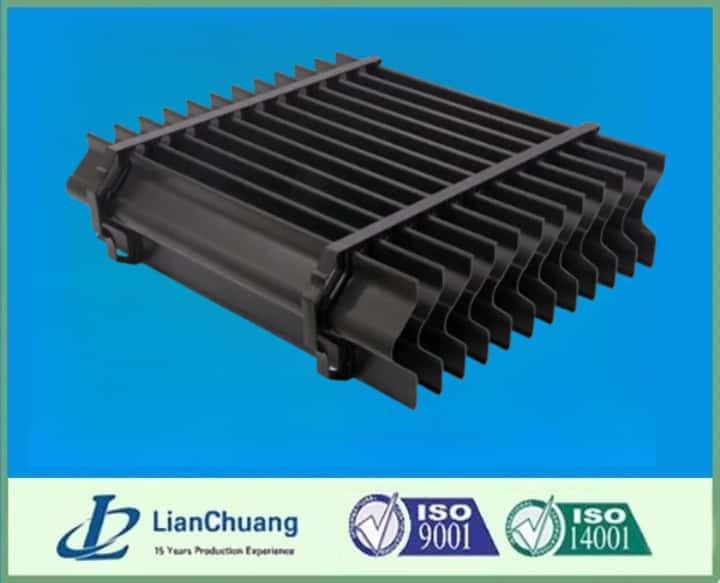

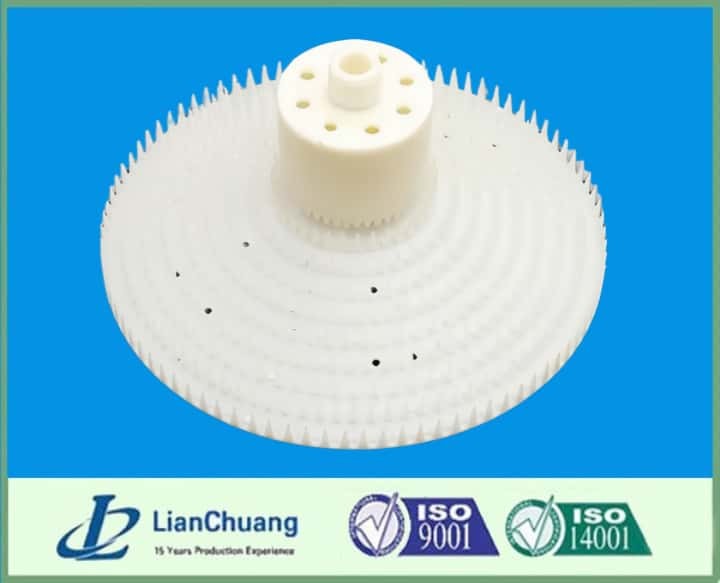

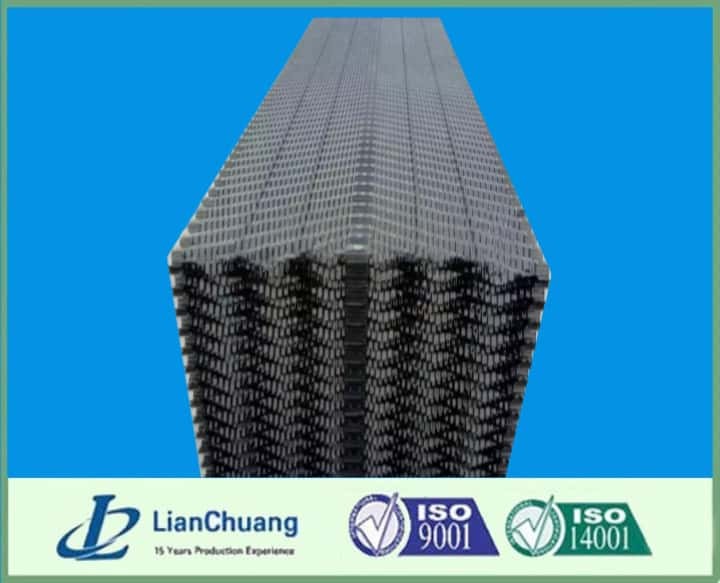

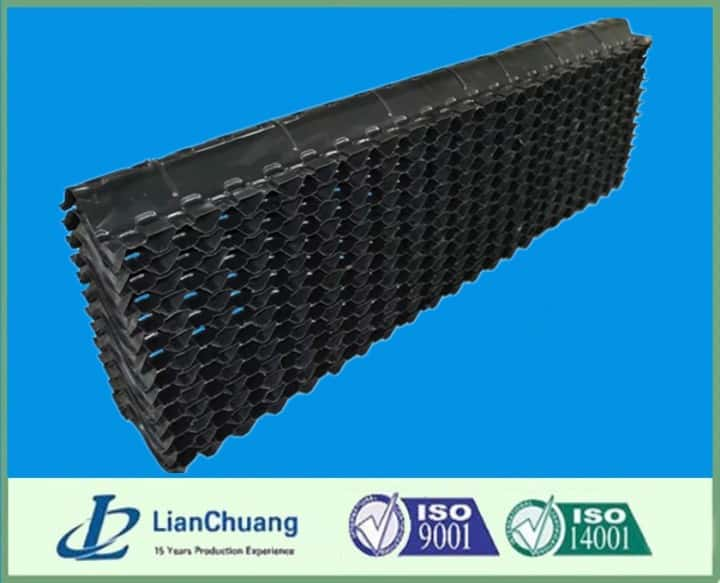

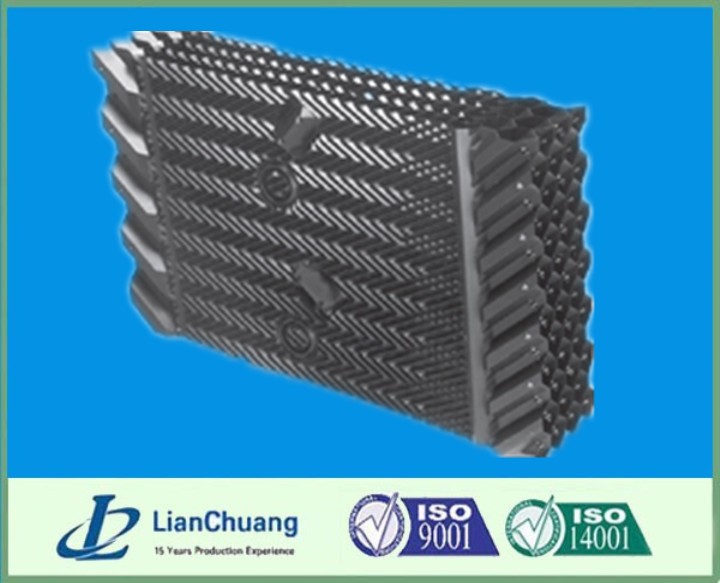

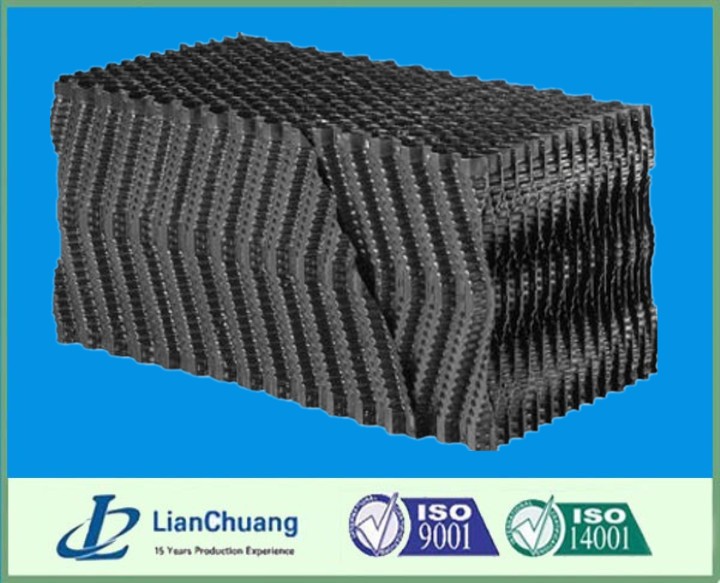

TAP155 , TAP160 are high-efficiency blade-type drift eliminators designed for large, field-erected cooling towers. These site-assembled units feature a modular spacer system that enables easy installation without the need for adhesives or solvents. Manufactured from UV-resistant polypropylene, they offer excellent droplet separation performance, long-term durability, and flexibility in sizing for a wide range of applications.

Key Benefits:

- High droplet separation efficiency – up to 99.5% separation at WL = 3 m/s

- Low pressure drop – improves system energy efficiency

- Site-assembled design – no adhesives or solvents required for assembly

- Flexible dimensions – adaptable to project-specific requirements

- UV and heat resistant – rated for short-term temperatures up to 80°C

- Environmentally friendly – made from recyclable polypropylene

Additional Information:

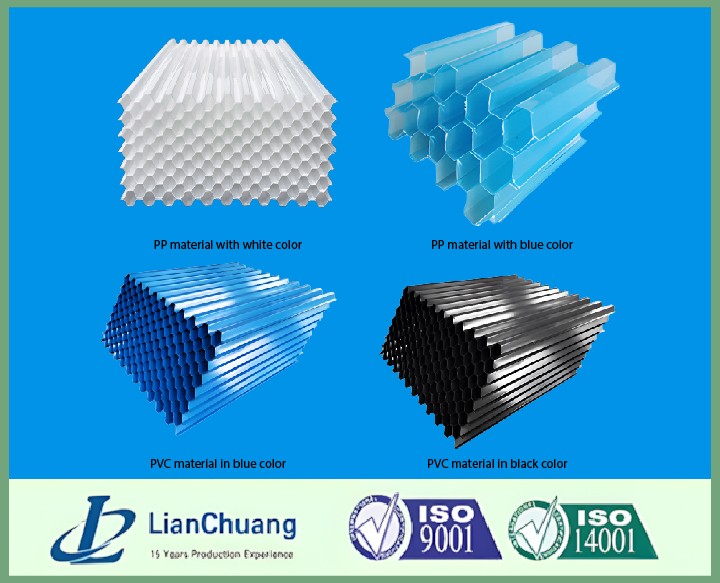

Material: UV-resistant Polypropylene

Service Temperature: Up to 80°C (short-term)

Shipping Weight: Approx. 380 g/m²

Droplet Separation: Approx. 40.1 µm at 3.4 m/s

Maximum Face Velocity: Approx. 4.5 m/s

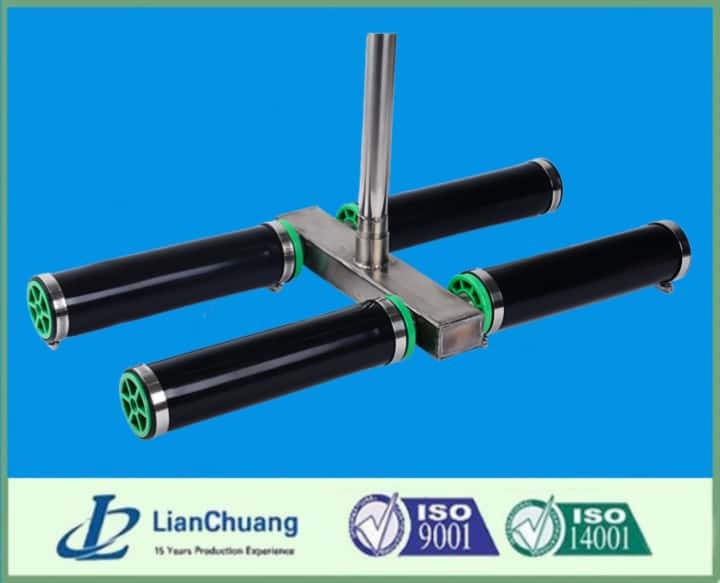

Spacer Options:

- TAS 033 – 33 mm spacing, 10 profiles per spacer

- TAS 738 – 38 mm spacing, 7 profiles per spacer

Technical Specifications:

| Product | Blade Spacing (in) | Depth (in) | Width (in) | Length (ft) | Blade Thickness (mils) | Dry Weight (lbs/ft²) |

| TAP 155 | 1.50 | 6.10 | 18.03 | 11.81 - 236.22 | 80 | 2.06 |

| TAP 160 | 1.30 | 6.30 | 13.39 | 11.81 - 236.22 | 80 | 2.59 |