Product Description

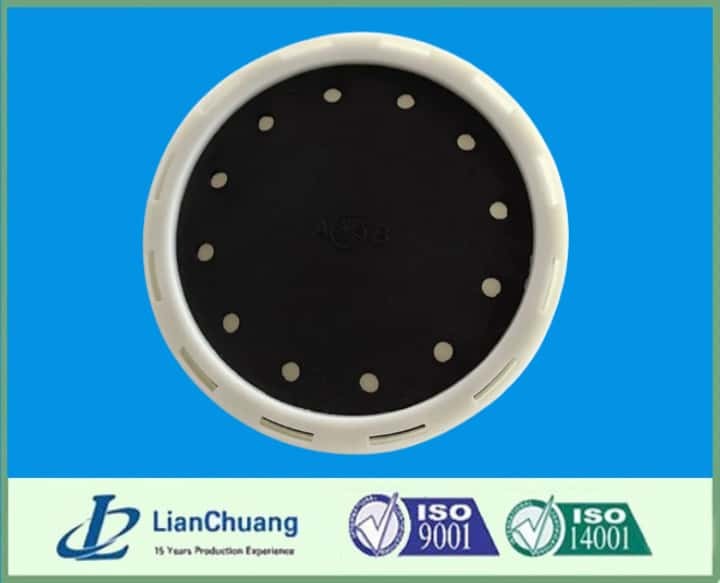

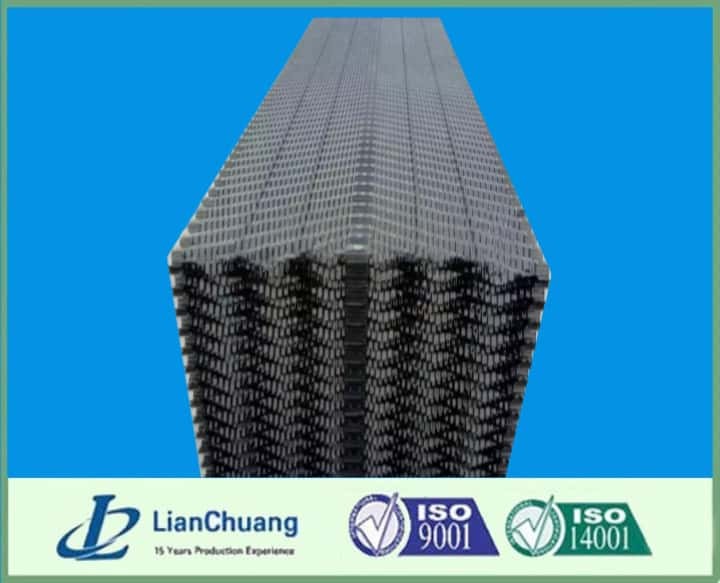

The coarse bubble air diffuser is a widely used aeration device in municipal wastewater treatment plants and industrial effluent treatment systems. It works by releasing larger-diameter bubbles into the water, ensuring efficient oxygen transfer and powerful mixing. Compared with fine bubble diffusers, coarse air diffusers are valued for their clog-resistant performance, ease of maintenance, and robust mixing capabilities. This makes them especially suitable for applications with high solid content, sludge-rich environments, or more complex water quality conditions.

Key Features

1. The coarse bubble diffuser is designed to combine reliability with operational efficiency. It provides effective oxygen supply and water circulation while keeping long-term maintenance needs minimal. Some of the most notable features include:

- 2. Efficient Oxygen Transfer: Larger bubble design ensures optimal residence time in the water, allowing a stable oxygen transfer process that promotes microbial activity.

- 3. Anti-Clogging Design: With wider openings, the diffuser is less likely to be blocked by sludge, fibers, or suspended solids, making it ideal for heavy-duty use.

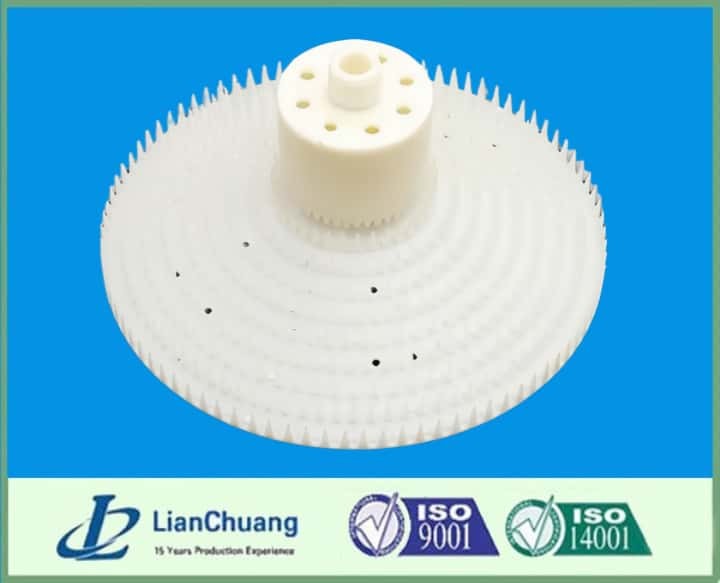

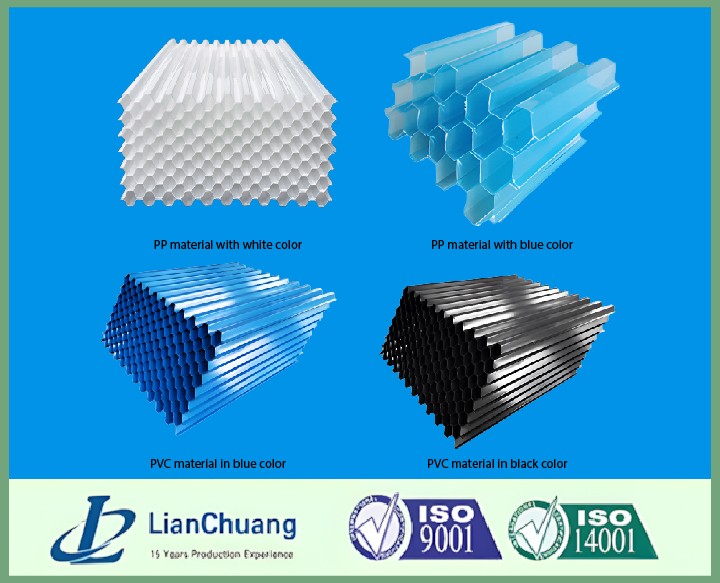

- 4. Durable Materials: Manufactured from corrosion-resistant stainless steel or high-strength engineering plastics, providing durability in harsh wastewater conditions.

- 5. Low Maintenance Costs: Simple structure and easy installation minimize downtime and reduce the frequency of maintenance operations.

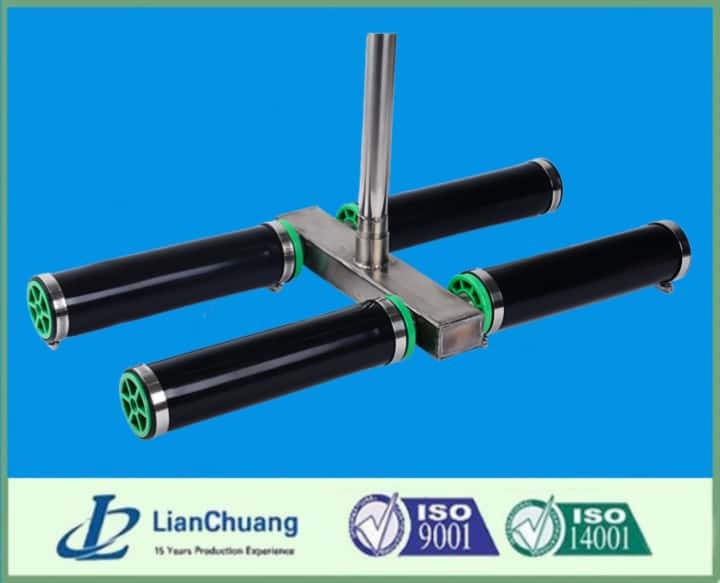

- 6. Flexible Applications: Suitable for aeration tanks, bioreactors, equalization basins, and even deep-water oxygenation projects.

- Energy Saving: Optimized bubble distribution lowers energy consumption while maintaining treatment performance.

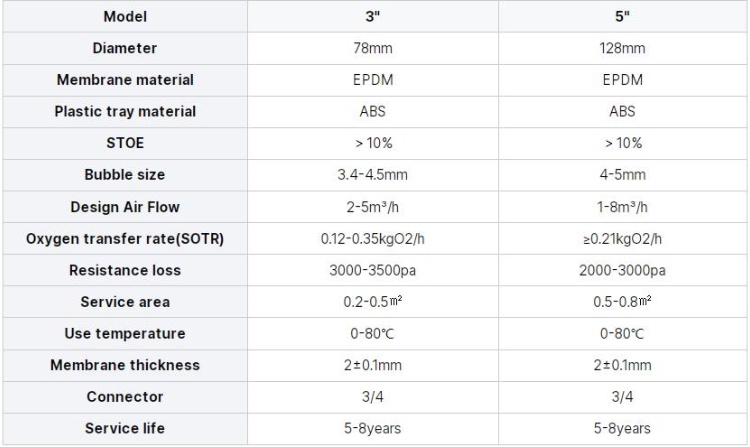

Specifications

Application Areas

1. coarse bubble diffusers are highly versatile and have been applied across various treatment stages and environmental engineering projects. The most common application areas include:

- 2. Aerobic Digestion: Traditionally, coarse bubble diffusers are used in aerobic digestion tanks. They ensure mixing and sufficient oxygen supply with a standard design rate of 30 scfm per 1,000 ft³ of tank volume.

- 3. Thickened Sludge Treatment: In high-solid concentration environments, a coarse air diffuser provides the aggressive aeration energy needed for proper mixing and oxygen transfer.

- 4. Auto-Thermophilic Aerobic Digestion (ATAD): For high-temperature, high-solids applications, coarse bubble diffusers with backflow prevention perform reliably. Material selection is important to withstand elevated operating temperatures.

- 5. Small or Package Treatment Plants: In compact systems where energy is less critical, coarse bubble diffusers are ideal due to their simplicity and durability.

- 6. Air Stripping: The large air-handling capacity of coarse bubble disc diffusers makes them effective for removing volatile compounds from groundwater and industrial wastewater.

Installation and Maintenance

Installing a coarse bubble diffuser is straightforward. Units are anchored at the bottom of the tank, with pipelines securely connected to ensure even airflow distribution. Maintenance is simple: periodic checks for blockages are recommended, and diffusers can be flushed with clean water or mild cleaning solutions when necessary. Avoid prolonged exposure to extremely acidic or alkaline conditions to extend service life.

Product Advantages

The coarse bubble diffuser is recognized as a cost-effective, reliable, and durable solution in the wastewater treatment industry. Compared with fine bubble technology, it provides stronger resistance to clogging, making it especially useful in sludge-heavy and viscous wastewater environments. For projects requiring strong mixing energy, the coarse bubble disc diffuser offers excellent stability and long-term operational efficiency.

By balancing performance, affordability, and ease of use, coarse bubble diffusers remain a preferred choice for engineers and operators looking to optimize oxygen transfer and mixing in demanding treatment conditions.