Product Description

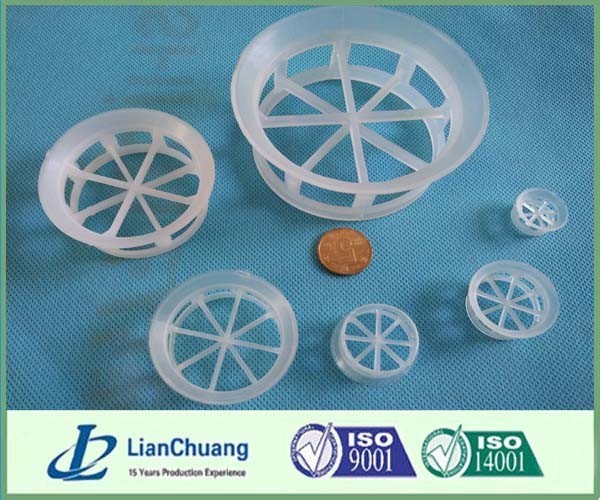

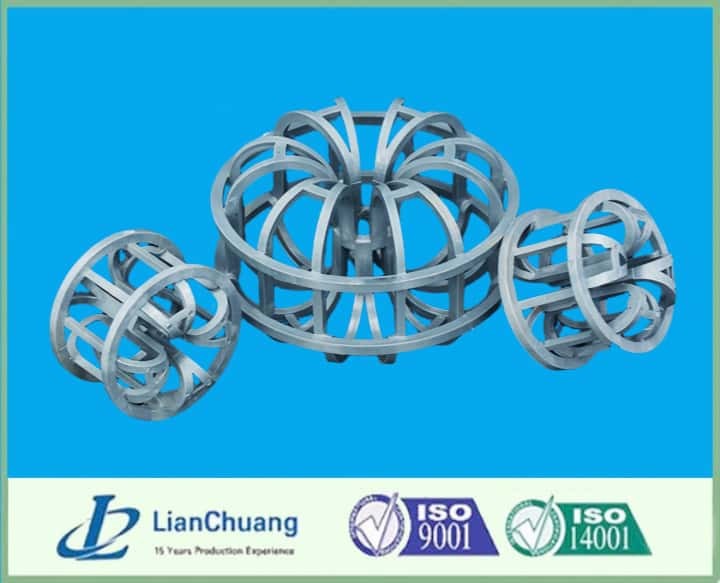

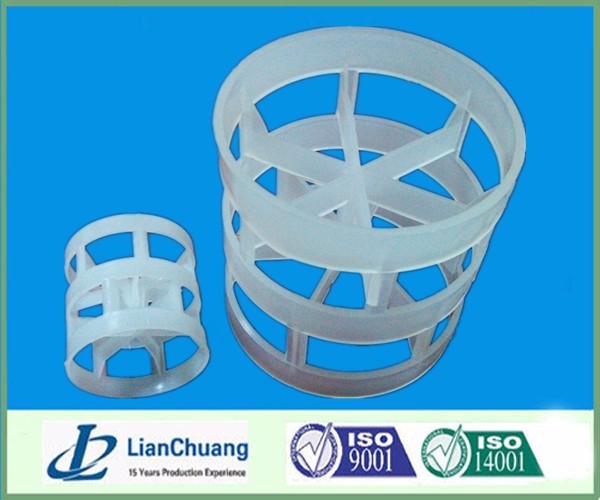

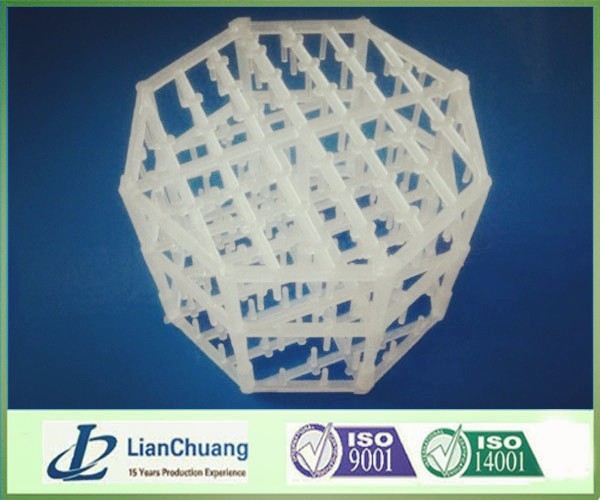

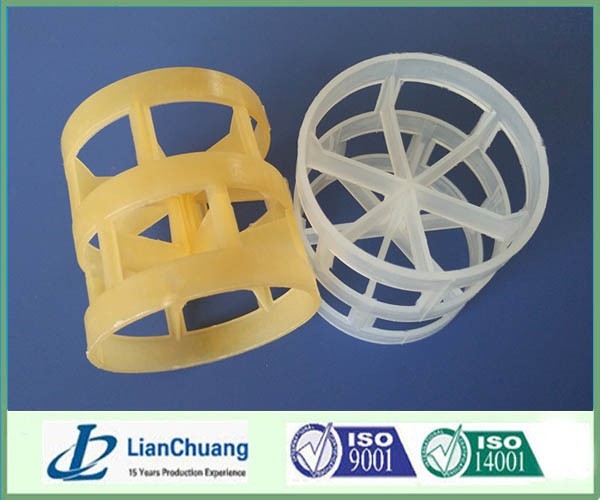

The plastic ladder ring, also known as plastic cascade ring, is a new generation of high-performance random tower packing. With its special cone-shaped flanging design on the edge, it reduces airflow resistance, increases void space, and improves gas-liquid distribution inside the tower. The height-to-diameter ratio of the plastic cascade ring is typically 1/2 or 1/3, allowing better orientation during installation and maximizing surface utilization.

The plastic cascade mini ring offers outstanding advantages such as lightweight structure, corrosion resistance, large specific surface area, high void fraction, uniform gas-liquid contact, and excellent mass transfer efficiency. It has become one of the most widely applied random packings in chemical, petroleum, and environmental industries.

Technical Data of Plastic Ladder Ring

| Specification | D*H*T (mm) | Number per m³ | Bulk Density (kg/m³) | Surface Area (m²/m³) | Free Volume (%) | F Factor (m-1) |

|---|---|---|---|---|---|---|

| Dg16 | 16×8.9×1.1 | 299136 | 135.6 | 370 | 85 | 602.6 |

| Dg25 | 25×12.5×1.4 | 81500 | 97.8 | 228 | 90 | 312.8 |

| Dg38 | 38×19×1 | 27200 | 57.5 | 132.5 | 91 | 175.8 |

| Dg50 | 50×25×1.5 | 10740 | 54.8 | 114.2 | 92.7 | 143.1 |

| Dg76 | 76×37×3 | 3420 | 68.4 | 90 | 92.9 | 112.3 |

Material Properties of Plastic Cascade Mini Ring

The plastic cascade mini ring can be manufactured from a wide range of heat-resistant and corrosion-resistant thermoplastics, ensuring durability under various operating conditions. Available materials include PE, PP, RPP, PVC, CPVC, and PVDF.

| Performance / Material | PE | PP | RPP | PVC | CPVC | PVDF |

|---|---|---|---|---|---|---|

| Density (kg/m³) | 0.94–0.96 | 0.89–0.91 | 0.93–0.94 | 1.32–1.44 | 1.50–1.54 | 1.75–1.78 |

| Operation Temp. (°C) | 90 | >100 | >120 | >60 | >90 | >150 |

| Chemical Resistance | Good | Good | Good | Good | Good | Good |

| Compression Strength (Mpa) | >6.0 | >6.5 | >7.0 | >6.0 | >8.0 | >10.0 |

Applications of Plastic Ladder Ring Packing

- Decarbonization and desulfurization systems in synthetic ammonia plants

- Crude oil separation towers

- Methanol separation and organic acid recovery processes

- Absorption and desorption towers in chemical and environmental industries

- Gas treatment, wastewater treatment, and other mass transfer applications