Product Description

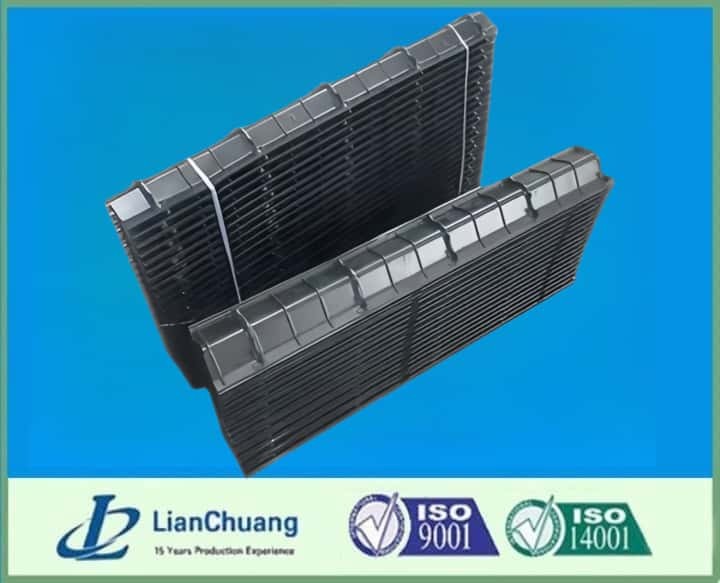

The DE120 Blade drift eliminator features sinusoidal-shaped blades made from PVC or HPVC that effectively remove drift droplets by forcing the airflow through three directional changes. With a blade spacing of 1.2 inches, it balances excellent drift removal performance with low pressure drop, making it the most economical drift eliminator in the lineup.

The blades are joined using one-piece end caps, forming lightweight yet durable modules that can span up to 6 feet between supports. This construction reduces material and labor costs while minimizing airflow resistance.

Designed with an open drainage system ideal for crossflow induced draft towers, the modules nest tightly with adjacent packs to eliminate gaps that could allow drift bypass. Tested under CTI-HBIK Standard 140, the drift loss is as low as 0.005% of circulating water flow. Materials meet CTI Standard 136 requirements.

Weights & Span Capabilities

| Blade Thickness | Dry Weight | Maximum Span |

|---|---|---|

| 25 mils (0.64 mm) | 0.9 lbs/ft² (4.4 kg/m²) | 6 ft (1.8 m) |

Dimensions

| Spacing | Width | Length |

|---|---|---|

| 1.200 in (30.5 mm) | 24 in (610 mm) | 1 to 12 ft (305 to 3660 mm) in 2 ft (610 mm) increments |

The DE120 modules are easy to assemble on-site, which benefits international projects by reducing freight costs through shipping unassembled components.