Product Description

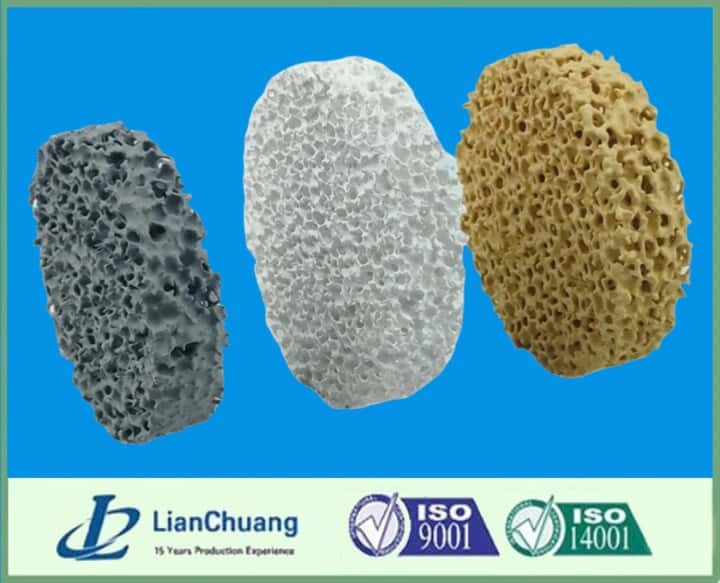

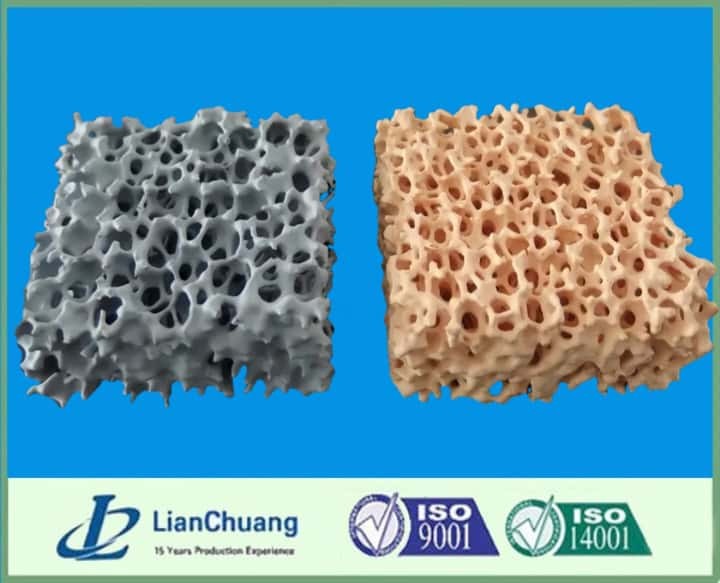

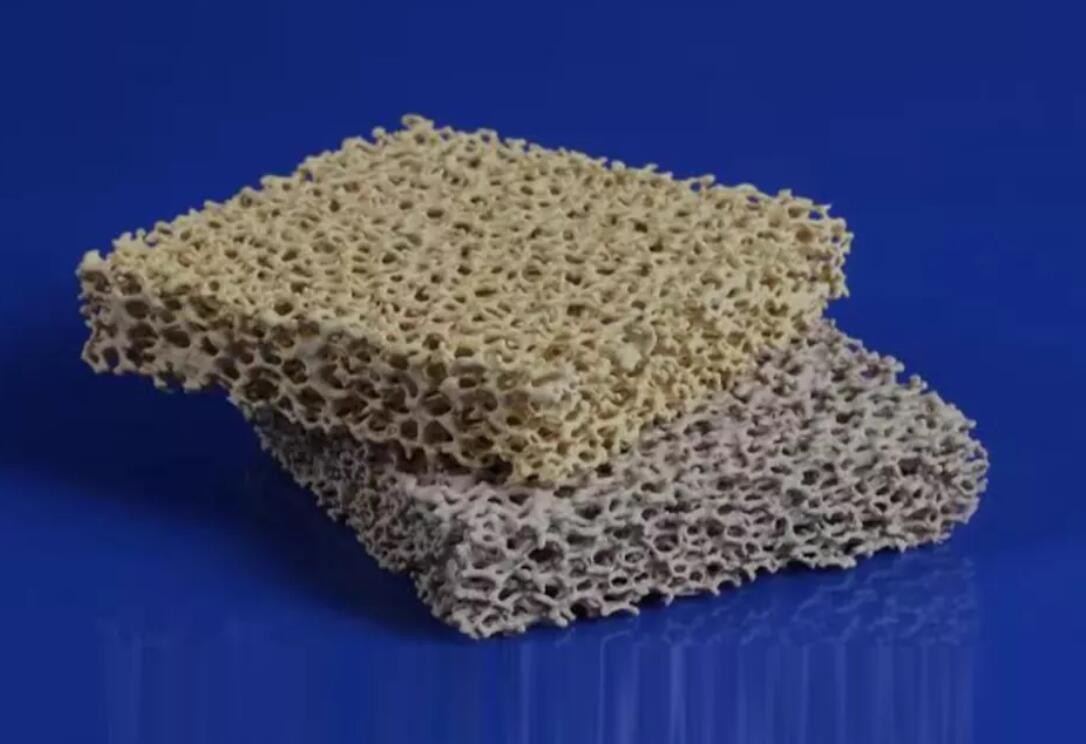

Zirconia Ceramic Foam Filters are specially designed for filtering various types of steel, including unalloyed, low-alloyed, stainless, and high-alloyed steels. These filters are highly recommended for high-quality alloys due to their excellent resistance to corrosion and molten steel attacks. zirconia ceramic foam filter significantly improve the filtration process by effectively removing inclusions, reducing trapped gases, and creating laminar flow. The result is cleaner filtered metal, which leads to better-quality castings, reduced scrap, and fewer inclusion defects.

These filters are ideal for use in steel casting filtration, specifically for steel alloys that require high temperatures of up to 1700°C. They are particularly recommended for high-quality alloy grades. By utilizing these filters, casting qualification rates improve, the metallographic structure enhances, and they are suitable for investment casting after preheating. Zirconia ceramic foam filters are the optimal choice for producing high-quality steel products with superior filtration capabilities.

Key Features of Zirconia Ceramic Foam Filters

- High-Temperature Resistance: Zirconia ceramic foam filters can withstand temperatures up to 1700°C, making them perfect for molten steel and high-alloy metals.

- Enhanced Filtration: These filters effectively eliminate non-metallic inclusions and reduce gas content in molten metal, ensuring cleaner metal for superior castings.

- Improved Casting Quality: By reducing defects and scrap, these filters increase casting yields and enhance overall casting quality.

- Investment Casting Compatibility: Zirconia ceramic foam filters can be preheated for investment casting applications, making them versatile for various casting needs.

- Environmental Compliance: Manufactured in compliance with ISO 9001:2015 standards and adhering to REACH and RoHS regulations, ensuring environmental safety.

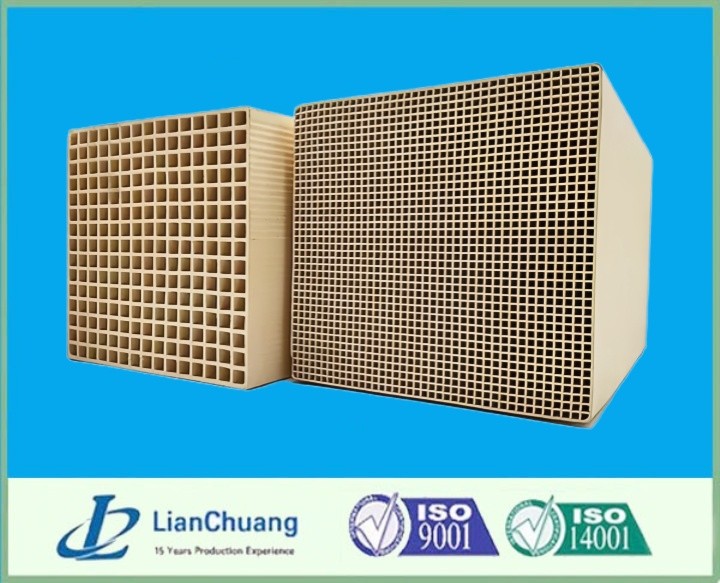

Technical Specifications of Zirconia Ceramic Foam Filters

| Property | Value |

|---|---|

| Material Composition | ZrO₂: 85–90%, Al₂O₃: 5–10%, SiO₂: ≤4%, MgO: 4–5% |

| Porosity | 80–90% |

| Bulk Density | 0.8–1.5 g/cm³ |

| Compressive Strength | ≥1.5 MPa (at room temperature) |

| Pore Density (PPI) | 10–40 PPI |

| Operating Temperature | Up to 1700°C |

| Thermal Shock Resistance | ≥6 cycles at 1100°C |

| Color | Yellow |

| Certifications | ISO 9001:2015, REACH, RoHS |

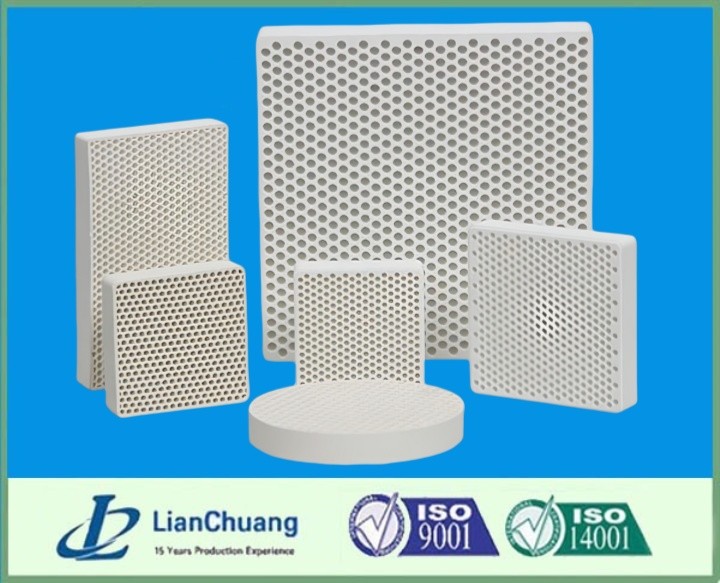

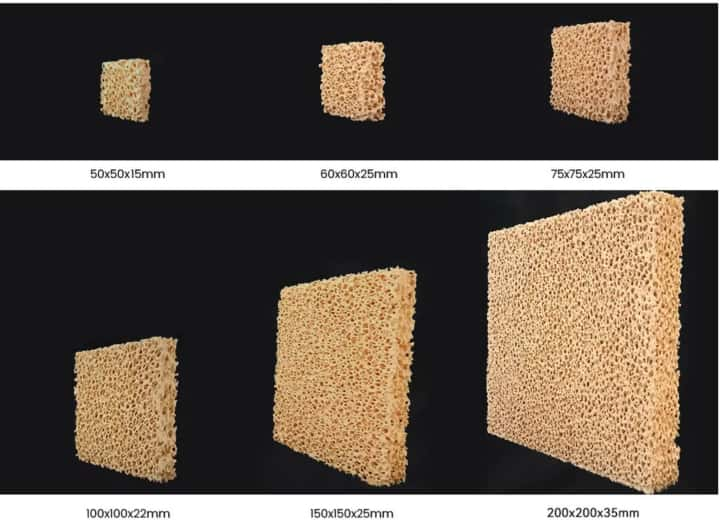

Standard Dimensions and Capacities

| Dimensions (mm) | Pouring Rate (kg) | Filtration Capacity (kg) |

|---|---|---|

| 50 × 50 × 22 | 3–5 | 30 |

| 50 × 75 × 22 | 4–6 | 40 |

| 75 × 75 × 22 | 7–12 | 60 |

| 75 × 100 × 22 | 8–15 | 80 |

| 100 × 100 × 22 | 14–20 | 100 |

| Ø50 × 22 | 2–6 | 18 |

| Ø80 × 22 | 6–10 | 50 |

| Ø90 × 22 | 8–16 | 70 |

Note: Custom sizes and thicknesses are available upon request.

Advantages of Zirconia Ceramic Foam Filters

- Precise Dimension Tolerance ensuring accurate fit and performance

- High Mechanical Strength to withstand demanding filtration environments

- Chemical Stability and Corrosion-Resistance for molten aluminum, preventing contamination

- Purifying Liquid Aluminum to improve quality and reduce defects

- Reduction in Defects by efficiently filtering out impurities

- Cost-Effective by reducing scrap and increasing yield rate

- Easy to Use with straightforward installation and operation

- Variety of Sizes ranging from 40mm to 600mm available for various casting needs

Applications of Zirconia Ceramic Foam Filters

- Cast Steel Industry: Ideal for filtering molten steel in steel casting applications.

- High-Temperature Gas Filtration: Can be used for filtering gases in high-temperature environments.

- Chemical Fillings and Catalysis Carriers: Employed as supports for catalytic reactions and chemical processes.

With their superior filtration capabilities, Zirconia ceramic foam filters are the optimal choice for high-performance filtration in steel casting and other demanding industries. Whether for investment casting, high-alloy steel filtration, or molten metal purification, these filters offer the reliability and efficiency required to ensure the production of high-quality, defect-free castings.