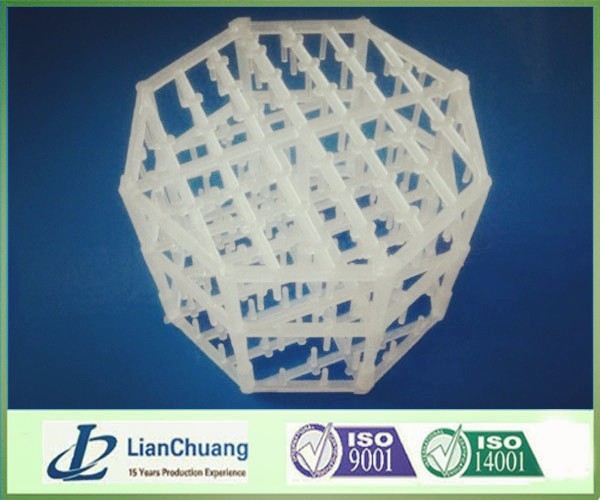

Product Description

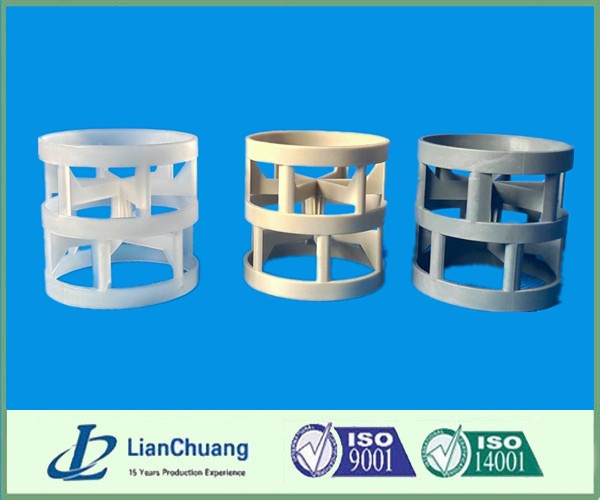

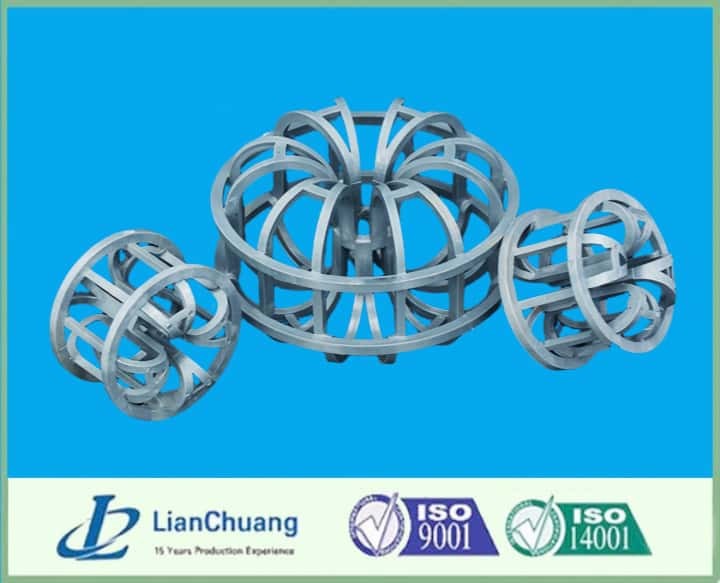

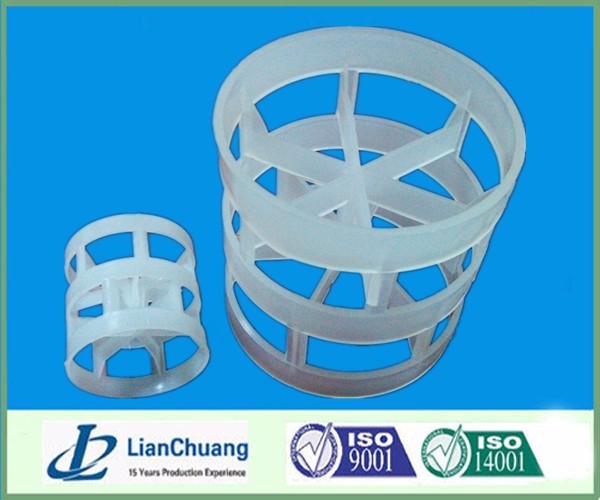

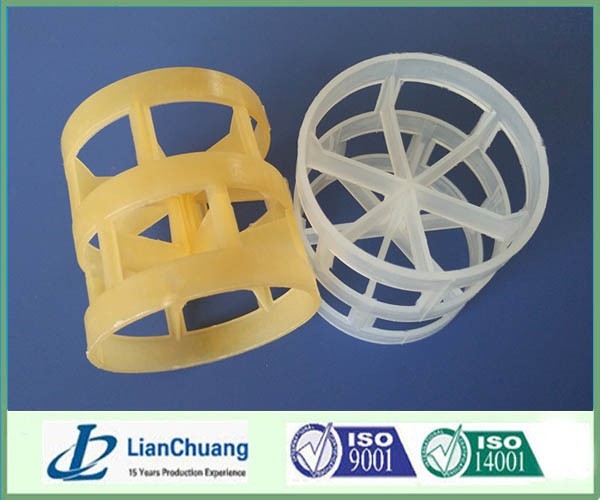

cpvc pall ring, rpp,hdpe and pvdf pall ring packings are improved from the raschig rings, pe rpp cpvc pvdf packing pall ring has similar cylindrical dimensions but has two rows of punched out holes, with fingers or webs turned into the centre of the cylinder, which significantly increases the performance of the packing, in terms of throughput, efficiency and pressure drop.

pe rpp cpvc pvdf packing pall ring is made from heat resistant and chemical corrosion resistant plastics, including polyethylene (PE), polypropylene (PP), reinforced polypropylene (RPP), polyvinyl chloride (PVC), chloridized polyvinyl chloride (CPVC) and polyvinylidene fluoride (PVDF). The application temperature in media ranges from 60 to 150. For these reasons pvc ,cpvc, pvdf plastic pall ring is widely used in the packing towers in petroleum industry, chemical industry, alkali-Chloride industry, coal gas industry and environmental protection, etc

Characteristics and advantages of different material Pall Rings in industrial applications:

PVC Pall Ring

Polyvinyl chloride (PVC) Pall Rings are favored for their excellent chemical stability and cost-effectiveness. They withstand corrosive chemicals and are suitable for mild process conditions, widely used in wastewater treatment and basic chemical reactions.

CPVC Pall Ring

Chlorinated polyvinyl chloride (CPVC) Pall Rings offer higher heat and corrosion resistance compared to standard PVC, making them suitable for harsher process conditions. They are commonly found in chemical processes under high temperatures, such as acid/base reaction towers.

PVDF Pall Ring

Polyvinylidene fluoride (PVDF) Pall Rings are highly regarded for their outstanding chemical resistance and high temperature performance. PVDF can withstand strong acids and bases, commonly used in petrochemicals, electronics, and specialty chemical production.

PE Pall Ring

Polyethylene (PE) Pall Rings are valued for their excellent abrasion resistance and chemical stability. They are used in handling mild chemical media and water treatment processes under low temperature and pressure conditions, offering an economical and practical solution.

RPP Pall Ring

Polypropylene (RPP) Pall Rings excel in corrosion resistance and mechanical strength, performing well in moderate temperatures and typical chemical environments. They are widely used in petrochemical and environmental industries, improving mass transfer efficiency and reducing energy consumption.

HDPE Pall Ring

High-density polyethylene (HDPE) Pall Rings exhibit good chemical stability and wear resistance, particularly suitable for moderate acid/base environments. HDPE Pall Rings are commonly used in wastewater treatment and metallurgical industries, providing reliable support for environmental protection and process optimization.

Features of plastic pall ring:

1) high void ratio

2) low pressure drop

3) sufficient gas-liquid contact

4) small specific weight

5) high mass transferring efficiency

Specification:

| D*H*T (mm) | Number per cubic meter | Bulk density (kg/m?) | Surface area (m?/m?) | Free volume (%) | F factor (m-1) |

| 16*16*1.1 | 112000 | 141 | 188 | 91 | 249 |

| 25*25*1.2 | 53500 | 150 | 175 | 90 | 239 |

| 38*38*1.4 | 15800 | 98 | 115 | 89 | 220 |

| 50*50*1.5 | 6500 | 74.8 | 112 | 90 | 154 |

| 76*76*2.6 | 1930 | 70.9 | 73 | 92 | 94 |