A degasser tower is used to remove dissolved gases from liquids and finds wide application in industries such as chemical processing and environmental management. In degasser towers, the choice of packing material is critical for gas removal efficiency and pressure drop within the tower. plastic pall rings offer several key advantages in this regard:

High Surface Area and Efficient Mass Transfer: The corrugated surface design of plastic Pall rings provides significant effective surface area, facilitating thorough liquid-gas contact and efficient mass transfer, thereby enhancing degassing efficiency.

Low Pressure Drop and Energy Savings: Due to their superior structural design, plastic Pall rings typically generate lower pressure drops for the same effect, reducing operational costs and energy consumption.

Chemical Stability and Corrosion Resistance: When handling corrosive media, plastic Pall rings maintain stability over extended periods, reducing maintenance and replacement frequency, thus lowering operational costs.

When it comes to selecting plastic pall rings for a degasser tower, choosing the right type is crucial for optimizing the efficiency and performance of the degassing process. This article explores the characteristics of plastic pall rings, their application in degasser towers, and how to choose the most suitable type to enhance process efficiency and cost-effectiveness.

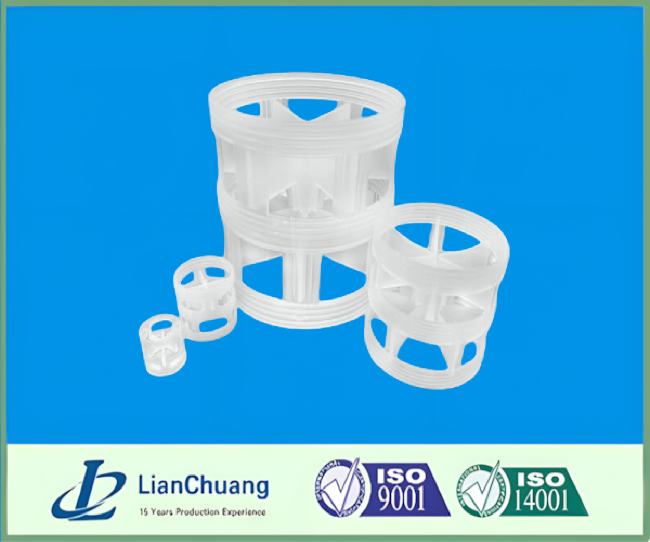

Characteristics of Plastic Pall Rings

Plastic Pall rings are commonly used packing materials known for several distinct characteristics:

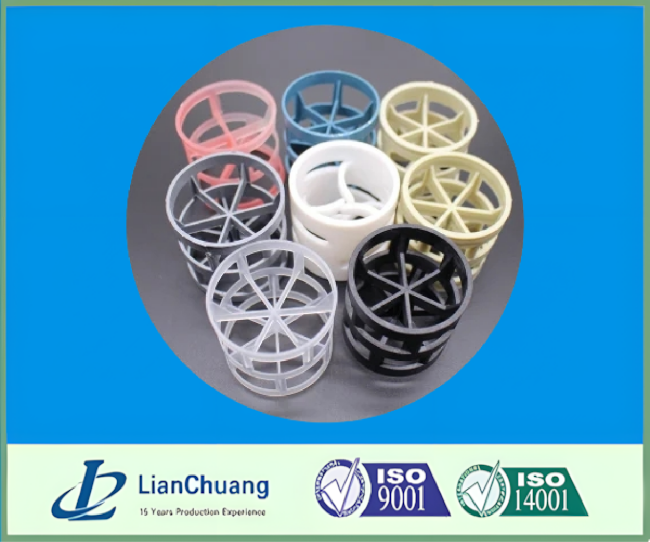

Chemical Stability: Typically made from materials like polypropylene (PP), polyethylene (PE), or polytetrafluoroethylene (PTFE), plastic Pall rings exhibit excellent chemical stability, able to withstand various corrosive environments.

Thermal Stability: They maintain stability across a wide range of temperatures, making them effective even in high-temperature degasser towers.

Surface Features: Plastic Pall rings are designed with a corrugated or geometric surface, which increases the surface area of the packing. This enhances liquid distribution and contact time on the surface, thereby improving mass transfer efficiency.

Abrasion Resistance and Durability: These properties contribute to a longer service life, maintaining performance under diverse process conditions.

Different material of plastic pall ring:

In the field of chemical engineering, the selection of packing materials plays a critical role in maximizing the performance and efficiency of degasser towers. Pall rings, a common type of tower packing, are highly regarded for their ability to enhance gas-liquid contact and improve mass transfer processes. This article explores the versatility and benefits of polypropylene, PTFE (Polytetrafluoroethylene), PVC (Polyvinyl Chloride), and PVDF (Polyvinylidene Fluoride) pall rings in degasser tower applications.

Polypropylene Pall Rings:

polypropylene pall rings are favored for their excellent chemical resistance and cost-effectiveness. They withstand a wide range of chemical environments, making them ideal for various industrial applications, including degassing. Their unique design promotes efficient gas-liquid contact, ensuring effective mass transfer and optimal separation within the tower.

PTFE Pall Rings:

PTFE pall rings are known for their exceptional chemical resistance, particularly against corrosive substances and high temperatures. Their non-stick properties prevent fouling and buildup, reducing maintenance and extending operational life. In degassing applications with aggressive chemicals, PTFE pall rings provide reliability and durability.

PVC Pall Rings :

PVC pall rings offer cost-effective performance with moderate chemical resistance. They are suitable for applications requiring resistance to acids, alkalis, and salts at lower temperatures compared to PTFE or PVDF. PVC pall rings perform well in degasser towers operating under mild chemical conditions.

PVDF Pall Ring:

pvdf pall rings combine excellent chemical resistance with high thermal stability, making them suitable for challenging industrial environments. They resist UV radiation and oxidation, ensuring durability in outdoor installations or harsh environmental conditions. PVDF pall rings excel in degasser towers handling aggressive chemicals or operating at high temperatures, providing robust performance and extended service life.

Conclusion:

Choosing the right plastic pall ring material is crucial for optimizing the efficiency and longevity of degasser towers. Polypropylene, PTFE, PVC, and PVDF pall rings each offer specific advantages depending on the chemical environment, temperature range, and operational needs. By selecting the appropriate material, engineers and operators can enhance gas-liquid contact, improve mass transfer efficiency, and achieve reliable separation processes in degasser tower applications. This ensures both performance excellence and cost-effectiveness in industrial settings.