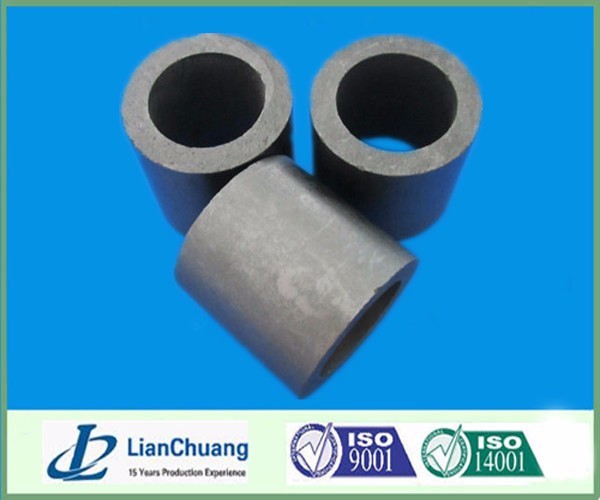

Product Description

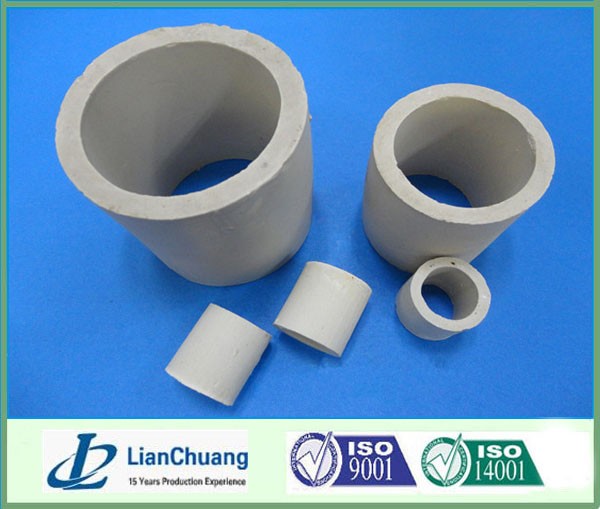

carbon raschig ring also called carbonized graphite raschig ring, carbon raschig rings are shapes of tubular carbon used in quantity to create a randomly packed bed for various material processing functions. This kind raschig ring made from Carbon or Graphite are used in specific applications demanding good corrosion and thermal shock resistance. carbonized graphite raschig rings are resistant to most acids, alkalis and solvents at temperatures as high as 150 dec. C and also display good erosion and thermal shock resistance. At the same time they have high crushing strength, thus have a long life.

Features of carbon raschig ring:

1.Consist of Entry Graphite Chamber, Distribution block, Multiple Process blocks and Exit Graphite Chamber

2.Low coefficient of thermal expansion; resists damage caused by severe shocks.

3.May be used in most acids, alkalies and solvent environments. (Not recommended in highly oxidizing conditions.)

4.Light in weight with high mechanical strength, having no soluble bond.

5.Long-life packing with high temperature operating capabilities.

6.Used in chlorine-hydrochloric mixtures and phosphoric acid.

7.Fully carbonized to eliminate extractable impurities.

8.High Thermal Conductivity.

Specification of carbon?raschig ring packing:

Size | Specification | No. elements | Bulk density | Specific surface area | Voidage | Net weight/pcs |

mm | mm | pcs./m3 | kg/ m3 | m2/ m3 | % | g |

13 | 13*13*2.5 | 400000 | 800 | 320 | 70 | 2.1 |

19 | 19*19*3 | 130000 | 669 | 265 | 67 | 5.4 |

22 | 22*22*3 | 72000 | 510 | 184 | 75 | 7.4 |

25 | 25*25*4.5 | 50500 | 700 | 160 | 70 | 13.8 |

32 | 32*32*5 | 25000 | 612 | 132 | 71 | 25.8 |

37 | 37*37*6 | 15570 | 640 | 130 | 66 | 41.1 |

40 | 40*40*6 | 12300 | 600 | 98 | 60 | 48.6 |

50 | 50×50×7 | 6750 | 570 | 86 | 74 | 84.5 |