Product Description

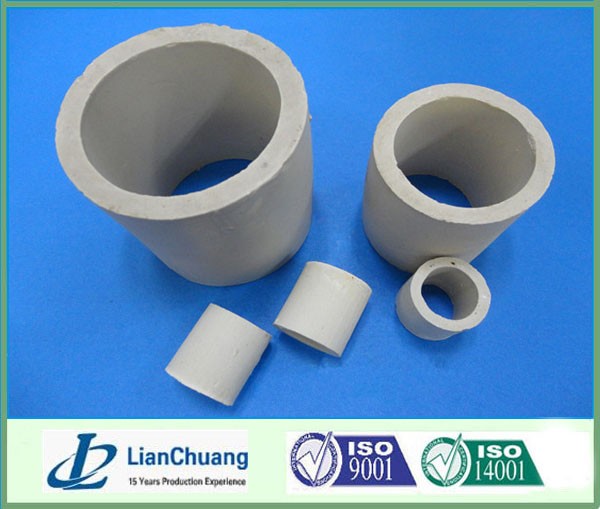

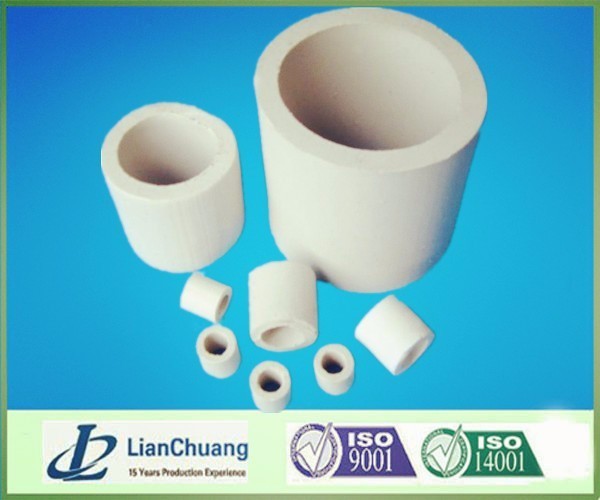

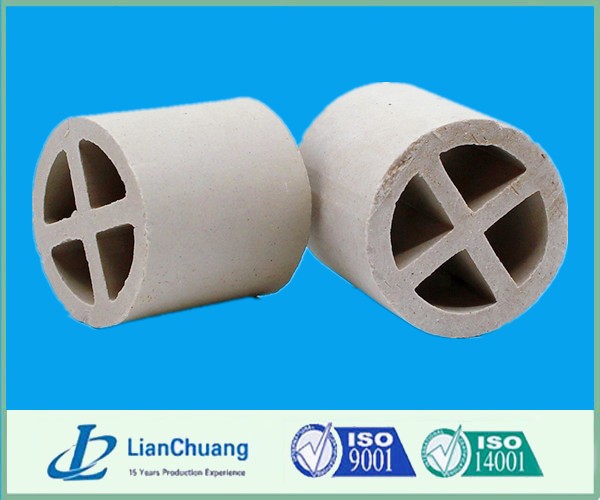

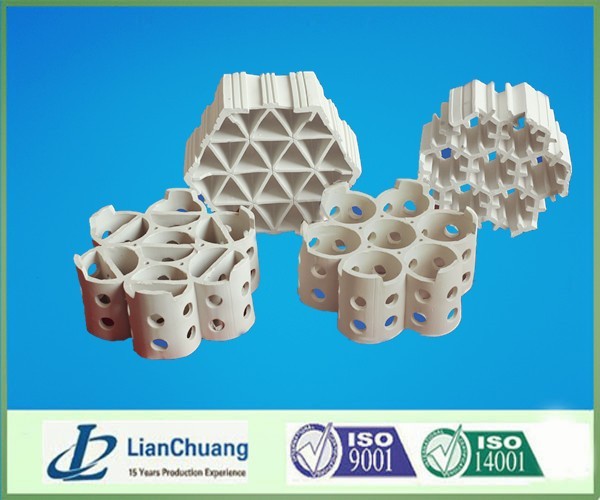

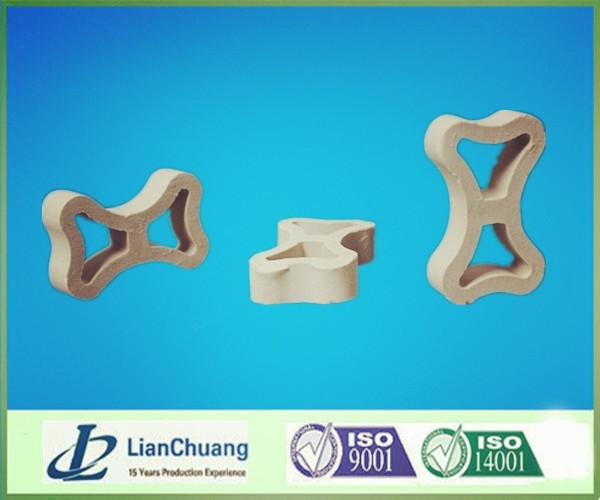

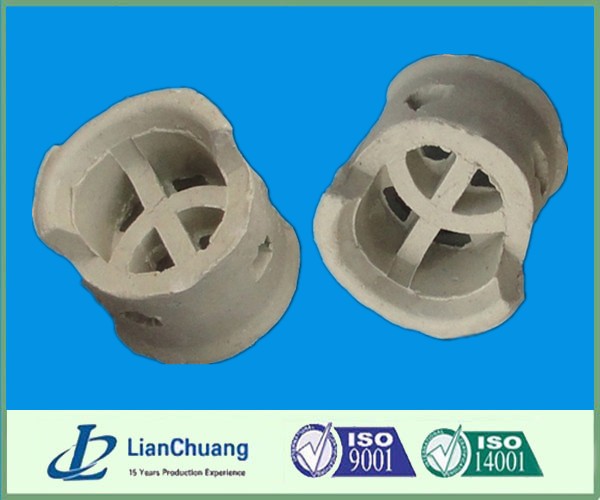

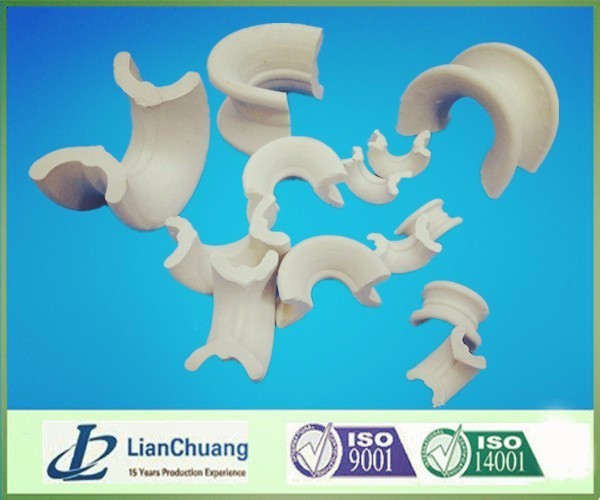

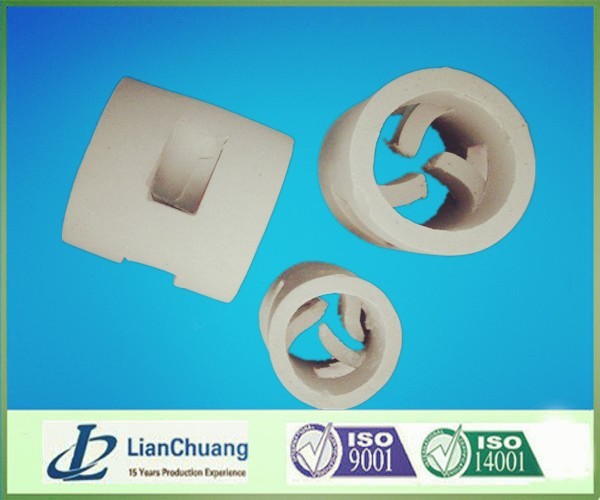

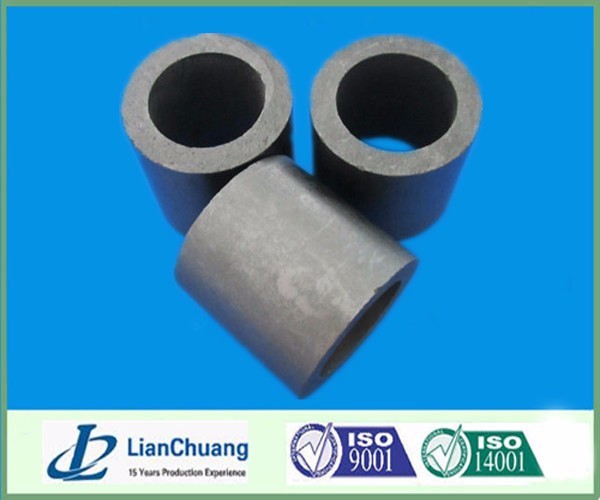

Raschig rings are named after the inventor, the German chemist Friedrich Raschig, ceramic raschig ring‘s a very simple ring shape with approximately equal in length and outside diameter. Ceramic raschig ring can resist to corrosion of various inorganic acids, organic acids and organic solvents except hydrofluoric acid, and ceramic raschig ring can be used in high or low temperature conditions. Raschig rings’ surface ratio is higher than ceramic cylinders and balls by 30% and its ring shape has high mechanical stability.

Ceramic raschig ring often used in large numbers as a packed bed within columns for distillations and other chemical engineering processes. They can provide a large surface area within the volume of the column for interaction between liquid and gas or vapour. And the form enabled Raschig to perform distillations of much greater efficiency than his competitors using fractional distillation columns with trays.( not ceramic saddles ) We has all kinds of size and material rasching ring, welcome contact and advise us which model you need.

Ceramic Raschig Ring product model:

3mm, 6mm, 10mm, 15mm, 25mm, 35mm, 40mm, 50mm, 76mm, 80mm, 100mm, 150mm

Specifications of Ceramic Raschig Ring:

Ceramic Raschig Ring | D*H*T mm | Specific surface area (m2/m3) | Void free volume(m3/m3) | Bulk number(n/m3) | Bulk density(kg/m3) | Dry packing factor(m-1) | |

Specifications ( inch/ mm ) | |||||||

1/8" | Φ3mm | 3*3*1 | 1620 | 0.82 | 10110000 | 1300 | 3850 |

0.25" | Φ6mm | 6*6*2 | 789 | 0.73 | 3110000 | 737 | 2030 |

0.4"; | Φ10m | 10*10*2 | 440 | 0.7 | 720000 | 700 | 1280 |

0.6" | Φ15mm | 15*15*2 | 330 | 0.7 | 250000 | 690 | 960 |

1" | Φ25mm | 25*25*2.5 | 190 | 0.78 | 50000 | 580 | 400 |

1.4" | Φ35mm | 35*35*4 | 150 | 0.76 | 18500 | 581 | 320 |

1.5" | Φ40mm | 40*40*5 | 126 | 0.75 | 13200 | 580 | 305 |

2" | Φ50mm | 50*50*5 | 93 | 0.81 | 6400 | 528 | 177 |

3" | Φ80mm | 80*80*9.5 | 90 | 0.68 | 1950 | 500 | 234 |

4" | Φ100mm | 100*100*10 | 70 | 0.7 | 1000 | 700 | 172 |

6" | Φ150mm | 150*150*15 | 50 | 0.68 | 295 | 790 | 142 |

Chemical Analysis of Ceramic Raschig Ring:

| SiO2 + Al2O3 | >92% | CaO | <1.0% |

| SiO2 | >76% | MgO | <0.5% |

| Al2O3 | >17% | K2O+Na2O | <3.5% |

| Fe2O3 | <1.0% | Other | <1% |

Physical properties of Ceramic Raschig Ring:

| Water absorption | <0.5% | Moh's hardness | >6.5 scale |

| Porosity (%) | <1% | Acid resistance | >99.6% |

| Specific gravity | 2.3-2.40 g/cm3 | Alkali resistance | >85% |

| Max operation temp | 1200℃ |

Package: Plastic bag, Jumbo bag, Carton box, Metal Drum etc.

Why Choose Us:

Cost Advantage: Operating within our factory premises provides us with a significant cost advantage, enabling us to offer competitive prices and providing you with more options for your procurement needs.

Excellent Quality: Our ceramic tower packing products are renowned for their superior quality, exhibiting outstanding resistance to acids, alkalis, and high temperatures, performing exceptionally well in various extreme environments.

Certified Manufacturer: We are a certified manufacturer, meeting industry-specific certification standards. This ensures that our products are reliable, compliant with standards, and instills the utmost confidence and support in your procurement decisions.

Timely Delivery: We prioritize customer experience, ensuring that each order is delivered accurately and on time. We understand that, for you, time is of the essence.